Focus on carbon: Unlocking embodied carbon reductions in facade systems

INTRODUCTION

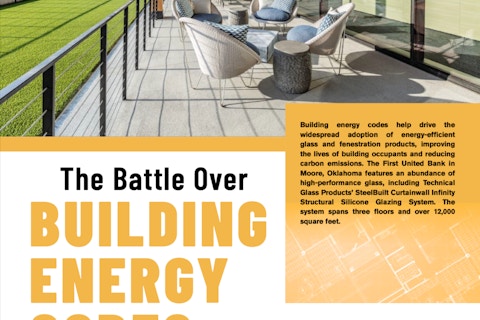

A recent report shows progress toward decarbonization in the building sector over the past two decades, but these gains have been almost exclusively in operational carbon emission reductions, while those of embodied carbon have been ignored. As these operational gains have progressed, the embodied carbon share of the carbon footprint has increased and been recognized as representing more than half of the whole-building carbon footprint for many buildings, becoming a focus for groups like Architecture2030, the Carbon Leadership Forum, and Building Transparency (Cutler et al. 2022).

Much of the initial focus on embodied decarbonization has been on concrete and steel, and for good reason; these materials are major contributors to global carbon emissions, much of that coming from their use in buildings (Global ABC 2022). As the carbon footprint of the structural elements continues to improve, the façade system will become an increasing focus of carbon reduction strategies.

This group—the Facade Tectonics Institute’s Embodied Carbon Working Group—has identified several critical areas of focus that will help unlock embodied carbon reductions in façade systems:

Increasing owner engagement

Setting project goals

Improving tools and education

Generating better data

Making informed supply chain decisions

These areas for improvement are interrelated and share some common challenges, but when tackled in parallel, can create a scenario in which embodied carbon can be reduced efficiently and cost-effectively through data, tools, and practices to meet defined targets. Digging deeper into each of these areas reveals several straightforward steps to improve a carbon-centered facade design process.

INCREASING OWNER ENGAGEMENT

Ownership represents a critical link in the building design and delivery chain, but owners often need to be more open to embed sustainability-related project goals in the mistaken perception that costs will surely outweigh benefits.

It’s important to differentiate between the interests of the spec developer and the owner-occupier. The spec developer is far more focused on short-term interests, while the owner-developer’s interests span the duration of projected occupancy. Shared interests include cost, schedule, quality, and risk mitigation. Beyond that, the spec developer is interested in features that will improve the market value of a building as reflected in lease and occupancy rates. The owner-occupier is generally more interested in environmental performance, involving the health and welfare of the occupant workforce and a workplace that enhances efficiency and productivity. Awareness of and interest in critical state, national, global, and organizational/institutional goals of resilience and sustainability is generally low and primarily limited to existing and anticipated code requirements.

This is short-sighted.

(Boland et al. 2022)Real-estate owners and investors will need to improve their climate intelligence to understand the potential impact of revenue, operating costs, capital costs, and capitalization rate on assets. This includes developing the analytical capabilities to consistently assess both physical and transition risks. Analyses should encompass both direct effects on assets and indirect effects on the markets, systems, and societies with which assets interact.

The ideal situation would be for ownership to bring sustainability goals to the design team, but this rarely occurs now in any meaningful way. For their part, architects and consultants on the design side may favor incorporating such goals but are not often assertive when it comes to making the case to ownership and may need to be prepared to make a compelling argument for the inclusion of such goals. The opportunity here is to make the business case for embodied carbon considerations in the facade systems of new building projects and the renewal of existing buildings. A suggested format is a concise, one or two-page report that clearly articulates the advantages from the owner’s perspective. This report should speak directly to the ownership’s interests, but also arm the design team with a solid argument to take to control.

The report should address how the inclusion of embodied carbon goals impacts the following considerations from the perspective of ownership, both in the short term and over time.

Risk mitigation

Costs

Schedule

Market perception and brand identity

The report should also include the following:

Suggested quantifiable goals for embodied carbon reduction.

Guidelines for the implementation and tracking of such goals.

Case studies of how embodied carbon goals have favorably impacted the bottom line of recent building projects.

SETTING PROJECT GOALS

Setting project-wide embodied carbon goals for the facade system in building projects has been difficult due to a misconception that it is too difficult and costly in the current construction industry. However, this stems more from a need for more understanding, awareness, and the skill of having the right conversations and ensuring implementation during the design, procurement, and delivery phases of projects. The easiest way to attack this problem is to educate project teams about embodied carbon in facades. The education and outreach effort at the start of all projects should include the following topics:

Holistic carbon design: Make whole-building carbon-informed design (including embodied and operational carbon) an overarching project priority. Optimizing the facade system, considering both embodied (facade+MEP) and operational carbon based on project characteristics and location, is key to decarbonizing the building sector (Oldcastle Building Envelope 2022).

Quantifiable goals: Set quantifiable goals for embodied carbon for the building and major building systems, including the facade system, as part of the initial basis of design.

Use less material: Measure and minimize material quantities, coordinate the design and engineering of assemblies and systems to minimize the quantity of materials, which may result in cost savings in addition to carbon savings (Vargas et al., 2021).

Material selection: Using sustainable and low embodied carbon materials is an effective strategy for reducing embodied carbon and, thereby, whole-building lifecycle carbon footprint. The location of source materials and local energy profiles must be included in these calculations.

Durability and resilience: Make durability and resilience key considerations in materials and façade assembly choices. Doubling the service life of an assembly or component halves the embodied carbon footprint. Materials that require less maintenance and are less easily damaged by extreme weather events reduce the occupancy-phase embodied carbon and the long-term impact of buildings, mainly by reducing the need for repair or replacement of components or systems.

Repurpose and recycle: Consider reusing/repurposing materials and/or using a high percentage of recycled materials. Even when embodied carbon numbers are similar, recycled material lowers the overall environmental impact compared with using virgin materials due raw material extraction and other impacts.

Design for disassembly and plan for end-of-life: How materials are repurposed, recycled, or disposed of at the end of the service life of a building should be a key consideration in facade assembly and system design. This will not affect the upfront project embodied carbon profile but is critical for circularity and whole-building lifecycle carbon emissions.

Consider policy alignments: A growing number of state and federal legislations are targeting low carbon procurement and impact disclosure by requiring Type III Environmental Product Declarations (EPDs) and setting embodied carbon limits for commonly used facade materials like glass, steel and insulation. Developers can align reduction goals with these targets to proactively prepare for upcoming embodied carbon building codes.

Consider project specifications: Project specifications could potentially incorporate many of the strategies discussed above so that all project stakeholders involved in project design and delivery can adopt these considerations in their design, procurement, fabrication, and installation practices. Example specifications could be developed and used for training and education purposes. Including such considerations in project documentation could considerably enhance the potential for success.

Projects highlighting the strategies discussed above must be documented and shared for training and education purposes.

While there have been advancements in understanding embodied carbon in building materials in recent years, there still are significant knowledge gaps related to facades.

IMPROVING TOOLS AND EDUCATION

While there have been advancements in understanding embodied carbon in building materials in recent years, there still are significant knowledge gaps related to facades. The complexity of façade components and supply chain, the necessary coordination among stakeholders, and the lack of quality data all contribute to this issue and have much room for improvement.

Key areas of progress and opportunity to strengthen resources and guidelines include:

Metrics, baselines, and best practices: The development and adoption of metrics, baselines, and best practices for the evaluation and optimization of embodied carbon considerations in buildings and facade systems are particularly important for code and standard development groups, as well as for building owners, real estate developers, and the design community. The emergence of new tools, like the Carbon Risk Real Estate Monitor (CRREM), to help real estate owners/developers/investors identify risks to their portfolio—helping to define which buildings would be considered "stranded assets'' in the face of climate change—is encouraging, and may help make the business case for the inclusion of embodied carbon considerations to the developers of new buildings, and owners of existing buildings considering renovation. Best practices also need to be updated to consider the full impact of HVAC systems on embodied carbon, including their refrigerants, which can significantly impact the whole building life cycle carbon.

Façade Emissions Data: More research is needed to develop accurate embodied carbon data for different facade materials. While available databases provide embodied carbon data for various building materials, facade materials are poorly represented, particularly for newer or less commonly used materials such as terracotta, GFRC, FRP, and certain types of stone, among others. Carbon Leadership Forum’s 2023 Material Baseline provides emissions data for aluminum, glass, insulation, sheathing, and metal cladding, which is a good starting point for measuring baseline impacts. Individual product vendors provide Type III EPDs, and material database platforms like 2050 Materials have Type III product-specific emissions data for a limited range of façade materials.

Method of Calculation: Whole-building LCA tools have versions of façade material quantity calculation based on proprietary assumptions, but a globally accepted standardized method for calculating embodied carbon for facades is lacking. Standardization will improve the accuracy and consistency of façade impact data. The Centre for Window & Cladding Technology (CWCT) provides a comprehensive methodology to calculate the embodied carbon of facades in project -specific applications, but is currently limited in application to the United Kingdom.

Stakeholder Education and Coordination: Design measures, specifications, and procurement strategies can significantly affect the embodied carbon impact of façades. It is critical to understand that the constituents involved in executing façade carbon impact reduction strategies often differ from those involved with other building systems, such as structural systems or interior finishes. While designers manage high-level decisions on aesthetics, geometry, and a basic material palette, façade consultants play an essential role in providing granular details on assemblies, components, finishes, and material quantities. General contractors and cost estimators can use this information to create a comprehensive bill of materials for embodied carbon calculations and procurement research for low carbon alternatives.

GENERATING BETTER DATA

Currently in the early stages, the volume and quality of embodied carbon data for façade systems is sparse and of low fidelity. EPDs requiring independent 3rd party certifications have spurred more rigorous and accurate data reporting of environmental impacts based on life cycle analyses. While this has helped generate publicly available global warming potential (GWP) data for various fenestration products, the next step is to produce quality data to accommodate the effective optimization of the embodied carbon of the facade system from early design through procurement.

Fenestration EPDs are typically comprised of a mix of primary and secondary data from 1-5 years old, averaged over multiple products, and reported concerning a single opening size. In addition, with some materials like aluminum, for example, there can be differences in the way pre and post-consumer scrap content is handled, adding additional uncertainty to certain facade framing systems. This lack of data accuracy and specificity makes it difficult to confidently define exacting design and purchasing decisions in pursuit of carbon footprint reductions.

The need is for a system and reliable methodology where impacts for a project are derived from up-to-date primary data* for a specific product, assembly, and façade system design. The concrete industry provides an example of how data reporting can be improved: there are EPD generators that have a validated calculation structure such that with varying material and energy inputs, new product-specific EPDs can be quickly and accurately created. On the primary data front, groups like the Aluminum Extruders Council and Rocky Mountain Institute are working to ensure that reporting methods are standardized and include higher quality information to allow accurate calculation of GWP impacts for aluminum. If the industry and product manufacturers embrace a shift to higher quality data and detailed reporting, this will spur further reductions in the embodied carbon of façade systems and be a valuable asset in building decarbonization in coming years.

SUPPLY CHAIN CONSIDERATIONS

A proper understanding of carbon-informed supply chain mechanics is a key component of carbon-informed design and successfully realizing established goals for reducing operational and embodied carbon. Historically, budget and time have been the predominant drivers of supply chain decisions, which has favored the selection of less expensive materials and products owing to lower labor costs, reduced performance attributes, and compromised durability and circularity potential. Carbon-informed procurement conversations rarely happen, relevant questions are not asked during the bidding and proposal process, and the consideration of embodied carbon needs to be addressed in procurement decisions.

The solution involves early onboarding of contractors and material suppliers and their engagement in a carbon-informed design-assist process that provides the necessary data points for an educated conversation about the operational and embodied carbon impacts of façade system procurement decisions. The method includes adequately structured BIM models with pre-populated databases shared among key stakeholders and used as the basis for decision making in a holistic bidding and product selection process (Karnath and Pennetier 2022).

The most important supply chain considerations for decarbonization should focus on raw materials and manufacturing. For example, the largest impact of typical aluminum curtainwall materials is in the cradle-to-gate (A1-A3) stages. Transportation cycles may represent a few percent of total embodied carbon (Hens et al. 2022), although it can be significantly higher with globe-spanning supply chains. As material sourcing and manufacturing processes decarbonize over time, transportation impacts will become more important and require sharper focus.

The availability of low-carbon solutions for typical material and product solutions is enmeshed in a complex web of interconnected considerations, including cost, resilience, finish, size, quantity, lead times, service life, and warranties, all of which must ultimately be balanced in realizing the owner’s project requirements and the architect’s basis of design. Carbon-informed supply chain management, paired with a robust, data-informed, and knowledgeable decision-making process, will be vital to reducing the carbon footprint of buildings and their facade systems.

CONCLUSION

Efforts to decarbonize buildings continue to gain momentum, but there are certain challenges the industry faces in the urgent need to speed this process along to support global resilience and sustainability targets in response to the climate crisis. A growing number of architects, engineers, and other stakeholders in the design-delivery process are highly motivated to reduce the embodied carbon footprint of buildings, but to do so will require more buy-in from owners and project stakeholders to establish and embrace specific carbon project goals, including embodied carbon. To properly set and meet these goals, the building and facade industries must be armed with better tools, more and higher quality data, and further education to empower these constituents with enhanced, carbon-informed decision-making capabilities involving façade system design and the supply chain that supports it. More sustainable, future-ready façade systems are within reach. Deep collaboration is needed across the building and facade industries in furthering the steps identified here.

* Primary data refers to emissions, energy, transportation and other information collected specifically for the manufacturing process being reported on rather than secondary data which can come from an LCA database or industry averages.

REFERENCES

Boland, Brodie, Cindy Levy, Rob Palter, and Daniel Stephens. “Climate risk and the opportunity for real estate.” McKinsey & Company. 4 February 2022. accessed 19 July 2023: https://www.mckinsey.com/industries/real-estate/our-insights/climate-risk-and-the-opportunity-for-real-estate

Cortes Vargas, T.C., Hildebrand, L., Rammig, L.M., Zani, Andrea. Carbon conscious! The impact of embodied emissions on design decisions for building envelopes. 2021. Accessed 25 June 2023: https://repository.tudelft.nl/islandora/object/uuid:f0368f8c-e7b6-4fa4-97ec-1e8e59555165

Cutler, Zak and Taylor Dayton, Matthew Grant, Shu’aib Mahomed, Jemilat Ojetayo. Reducing embodied carbon in new construction. McKinsey & Company. 17 October 2022: accessed 25 June 2023: https://www.mckinsey.com/capabilities/operations/our-insights/global-infrastructure-initiative/voices/reducing-embodied-carbon-in-new-construction#/

Global ABC 2022. 2022 Global Status Report for Buildings and Construction. Global Alliance for Buildings and Construction. Accessed 28 January 2024: https://globalabc.org/resources/publications/2022-global-status-report-buildings-and-construction\

Hens, Isabelle and Sophie Pennetier, Simon Schleicher. 2022. “Embodied Carbon Of Timber Unitized Curtain Wall.” Façade Tectonics World Congress Proceedings 2022. Accessed 19 July 2023: https://www.facadetectonics.or...

Karnath, Laura and Sophie Pennetier. “Decarbonize now: The next frontier in glass facade innovation.” IGS Magazine. 2 May 2022. Accessed 19 July 2023: https://igsmag.com/features/decarbonize-now-the-next-frontier-in-glass-facade-innovation/

Oldcastle Building Envelope. 2022. Reducing the footprint of your facade: A closer look at carbon in commercial fenestration. Accessed 19 July 2023: https://cdn.obe.com/wp-content/uploads/2022/06/OBE_embodied-carbon_ebook_062222-.pdf

Vargas, T.C. Cortez and Linda Hildebrand, L.M. Rammig, Andrea Zani. 2021. Carbon Conscious! The Impact of Embodied Emissions on Design Decisions for Building Envelopes. From Proceedings of the 9th PowerSKIN Conference. 2021-04-09, Munich, Germany. TU Delft Open. Accessed 19 July 2023: http://resolver.tudelft.nl/uuid:f0368f8c-e7b6-4fa4-97ec-1e8e59555165

This white paper was authored collectively by the Embodied Carbon Working Group of the Facade Tectonics Institute. Authors included:

Tom Bougher - Oldcastle Building Envelope

Shreya Das - Stok

Irene Martin - Arup

Mic Patterson - Facade Tectonic Institute

Sophie Pennetier - Enclos

Sanjeev Tankha - Starq Design

Andrea Zani - Permasteelisa

FTI Embodied Carbon Working Group

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.