Connecting Composites to Sustainability: Probabilistic LCA, Industrialized Construction, and Digital Twinning

Material flows of the fossil fuel industry, from exploration and extraction to distribution and combustion, are massive on a global scale. In 2019, the world produced approximately 80 million barrels of crude oil per day, with most being used as a feedstock for combustible fuels.[i] The oil and gas sector is a major part of our global economy, comprised of approximately 1,500 oil and gas firms listed on stock exchanges around the world, worth over a combined US$4 trillion. These firms, and the supply chains they support, form the economic foundation and largest employment sector for numerous countries in South America, Africa, Southeast Asia, and the Middle East, along with major geographic areas in Eurasia, and North America.

Global production of 80 million barrels of crude oil per day equates to approximately 4 gigatonnes of crude oil production annually. Globally, the construction industry consumes approximately 20 gigatonnes of construction materials annually.[ii] While a weight conversion from crude oil to construction materials is not 1:1, the construction sector is one of the few non-combustion applications with a large enough scale to consume the vast quantities of fossil-derived hydrocarbons (e.g.,

oil, natural gas) produced annually. Given global rates of urbanization[iii], the worldwide demand for construction materials is growing as a potential non-combustion alternative end use for fossil-derived hydrocarbons. Based upon this growing global need for infrastructure construction and renewal, and the growing global demand for more responsible stewardship of fossil-derived hydrocarbon materials, composites are gaining traction as a material for more sustainable construction around the world.

[i] "Production of Crude Oil including Lease Condensate 2019" (CVS download). U.S. Energy Information Administration.

[ii] Matos, G., (2017) Use of raw materials in the United States from 1900- 2014: USGS Fact Sheet 2017–3062, 6 p.

[iii] United Nations. (2018) “The Speed of Urbanization Around the World” New York, New York USA. Available at: https://population.un.org/wup/...

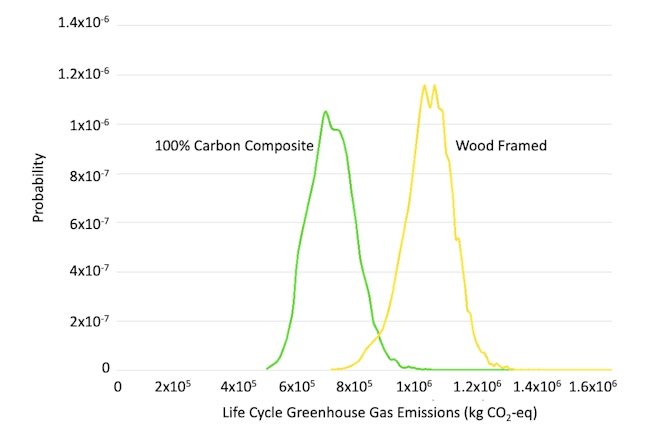

Probabilistic Life Cycle Assessment

There are several major trends and technologies now converging to alter the trajectory of composites as a more sustainable construction material. First, there is increasing interest in quantifying the role of composite materials in high performance, sustainable buildings and building systems. One example of has been the construction of the San Francisco Museum of Modern Art (SFMOMA) façade using polymer composite materials. Several preliminary studies have been conducted that point to the potential for composite facades to be a lower impact alternative to conventional façade materials such as glass fiber reinforced concrete. For example, preliminary analysis has shown that if the SFMOMA façade had been constructed using glass fiber reinforced concrete rather than glass fiber reinforced polymer composite, it would have resulted in greater life cycle emissions of particulate matter, greenhouse gasses, ozone depleting gasses, acidification emissions, eutrophication emissions, and non-methyl hydrocarbons. Ongoing research using probabilistic life cycle assessment approaches is also demonstrating the future potential for 100% composite buildings to significantly reduce life cycle greenhouse gas emissions of the built environment in the case of both conventionally constructed, wood framed multi-story residential structures and single-family homes. As seen in Figure 1, the probabilistic distribution of total global warming potential emissions (CO2-equivalents) for a 100% carbon composite multi-story residential is significantly less than a wood-framed multi-story residential building when using probabilistic LCA.

Figure 1. Probabilistic distributions of total life cycle global warming potential emissions (CO2-equivalents) for 100% carbon composite multi-story residential and a wood-framed multi-story residential building

Industrialized Construction

There is growing adoption of unique building forms that are enabled by NURBS representations in architectural design software. The design opportunity offered by composite materials, when coupled with advanced forms of industrialized construction, to now deliver these inspirational forms of the built environment is very exciting. An example of these forms in the urban landscape, which was mentioned previously, is SFMOMA. Recognizing that broader sustainability assessment of the built environment is comprised of environmental and social indicators, there is an emerging role for composite buildings and building elements to enable more awe inspiring, inclusively designed, and human-centered urban spaces.

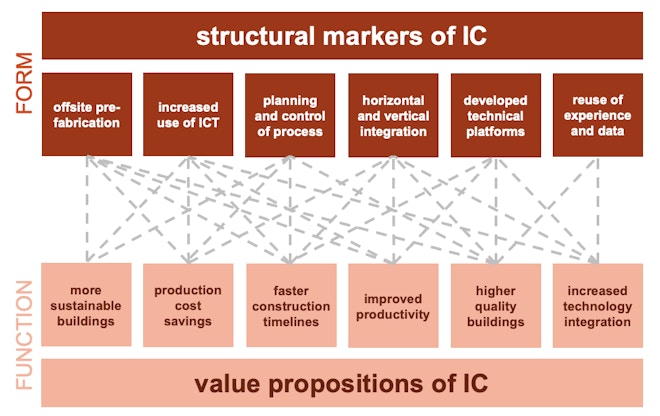

Moreover, composite materials, manufactured composite building elements, and robotic construction methods for composite structures are now seen as a pathway toward providing greater value propositions for the built environment, including sustainability-focused value propositions. As seen in Figure 2, there exist a number of structural markers that indicate the application of industrialized construction technologies and methods. These structural markers include offsite prefabrication, increased used of information technology, advanced planning and control, integration of horizontal and vertical construction, the application of technical platforms that leverage data, and the reuse of experience and data.[i] Each of these structural markers is prevalent in the composites construction sector. As shown schematically in Figure 2, these markers have been shown to result in increased value to building owners and stakeholders in the form of project cost savings, project schedule savings, productivity improvements, increased quality, increased use of technology.[ii],[iii] Most important for this discussion, such projects are demonstrating an increase in the sustainability of built environments that leverage industrialized construction methods.

[i] Lessing, J. (2006). Industrialized House-Building: Concept and processes, Licensiate thesis. Lund: Lund University.

[ii] Lessing, J., & Brege, S. (2015). Business models for product-oriented house-building companies – experience from two Swedish case studies.

[iii] McKinsey. (2017). Reinventing Construction: A Route to Higher Productivity. McKinsey & Company, February 20, 2017.

Figure 2. Pathways linking the structural markers of industrialized construction, including industrialized construction of composite structures, and the value propositions of industrialized construction, including more sustainable built environments

Digital Twinning of Built Environments

There is renewed interest in the durability of the built environment as a pathway to sustainability of the built environment. Composites represent one of the most durable building materials in use when designed and maintained appropriately. The recent tragedy of the Champlain Towers South condominium collapse in Surfside, Florida has also brought to the forefront the need for diligent management and care of the built environments in which we live, work, learn, and play. Advanced composite material technologies, coupled with new computational models for high-fidelity “digital twinning” of the built environment, are enabling data-driven design and management throughout the life cycle of constructed facilities beginning with early-stage programming to detailed design, fabrication, construction, commissioning, operation, and end of life management.[i]

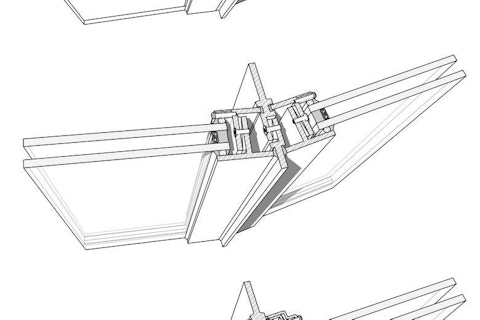

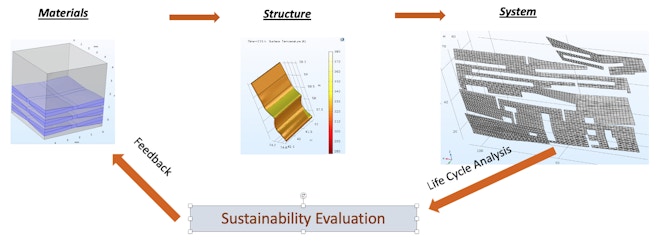

Through multi-physical multi-scale modeling, it is becoming possible to predict the future performance of building-scale systems based on fundamental physical characteristics and environments, and to relate future performance with physical and chemical processes taking place on scales ranging from micro-structural scale, to component scale, to building-level scale. For illustration, the architecture of a multi-scale, multi-physical model to predict the time-dependent aging and fatigue of a composite façade structure is shown in Figure 3.vii The model combines coupled transport of heat and matter, ultraviolet degradation, and fatigue-induced damage to predict the change in capacity over time.

[i] Li, Z. (2021) “Data-driven innovation in infrastructure management and financing” Sustainable Finance Research Workshop. Stanford Center at the Incheon Global Campus, Songdo, South Korea. August 26, 2021.

Figure 3. Multi-scale multi-physical “digital twin” architecture of a composite architectural façade capturing the interaction of such digital twins with sustainability evaluation models

Sustainable Multi-scale Built Environments

A number of challenges have been identified confronting US infrastructure systems and built environments. The major challenges related to sustainable infrastructure and building systems include a lack of reliable models for long-term economic cost, social benefit, and environmental impact predictions and a lack of robust decision-making tools and frameworks that incorporate real-world performance data and can consider innovative new technologies.[i] As a designable material system, composites represent a unique opportunity for architects, engineers, fabricators and builders to approach the challenge of sustainable built environments in new and innovative ways to overcome some of these major hurdles.

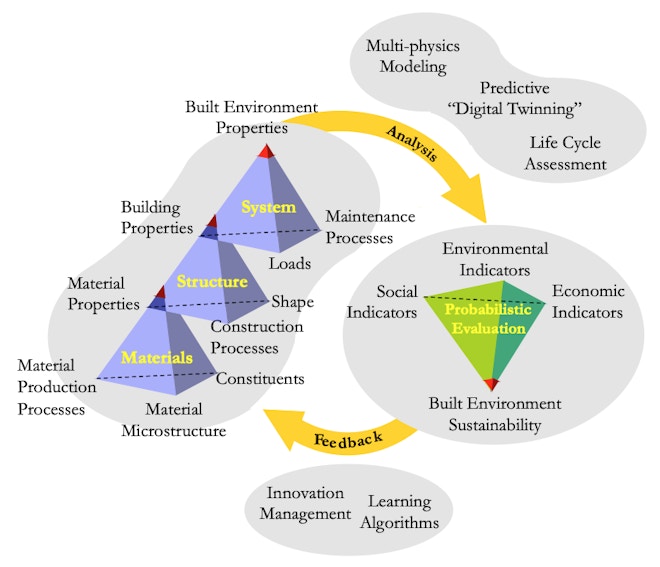

As shown in Figure 4, such opportunities are captured in the Sustainable Integrated Materials, Structures, Systems (SIMSS) framework now being used for design and evaluation of sustainable multi-scale built environments.[ii] The SIMSS framework enables improved measurement of impact through the development of high-fidelity quantitative sustainability assessment methods that empower designers to quickly and probabilistically measure sustainability indicators (right side of Figure 4). The framework also leverages multi-scale, fundamental design and engineering tools that integrate with sustainability assessment and facilitate setting and meeting sustainability targets throughout the life cycle of built facilities (left side of Figure 4). Thus, SIMSS brings together design concepts, models, and tools that are tightly integrated with quantitative sustainability assessment and service life modeling across length scales, from material scales to system scales, and throughout the early design, project engineering, construction, and operation life cycle phases of built environments.

[i] Moncarz, P., Lepech, M. D. (2018), “A vision for the future of America’s infrastructure,” National Academy of Engineering The Bridge 48(2): 3-5.

[ii] Expanded from Lepech, M., G.A. Keoleian, and V.C. Li (2007) “Integrated Structure and Materials Design for Sustainable Concrete Transportation Infrastructure” International Society for Industrial Ecology Conference 2007. Toronto, Canada. June 17-20, 2007.

Figure 4. Sustainable Integrated Materials, Structures, Systems (SIMSS) Design Framework

Conclusion

Unsustainable energy and material consumption, waste production, and emissions associated with the construction, operation, and demotion of the built environment are some of today’s most pressing global concerns. To address these concerns, designers need more sustainable multi-scale building technologies that, for example, passively generate power, reuse waste, and are carbon neutral. Composite materials, when combined with probabilistic life cycle assessment methods, modeled using new digital twinning computational capabilities, and designed within a multi-scale, circular building system have the potential to be a significant piece of solving our pressing global sustainability challenge.

Acknowledgments

The author would like to gratefully acknowledge the staff and students in the Department of Civil and Environmental Engineering that conduct research into the areas of sustainable built environments and material technologies including Dr. Zhiye Li, Dr. Jie Wu, Ms. Teresa Hegarty, and Ms. Melissa Zirps. The author would also like to thank the Precourt Energy Institute at Stanford University and ExxonMobil Corporation for their support of this research. This work was supported, in part, through the Stanford Center at the Incheon Global Campus.

Michael D. Lepech

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.