The Energy Performance of Mid-Century Metal-and-Glass Curtain Walls

1. Introduction

The assumption that mid-century buildings with single-glazed, curtain wall systems are less energy efficient than modern buildings often is used to justify demolishing these buildings or replacing or overcladding their facades, many of which are significant examples of Modernist architecture. This assumption neglects the effect of the often poor efficiency of the existing older mechanical equipment on the building’s overall energy profile. Sometimes, the curtain wall contributes less to the overall building energy performance than heating/cooling, ventilation, and lighting. As a building’s surface area-to-volume ratio decreases (i.e., taller buildings), the envelope load’s contribution to the total energy use also decreases, particularly for heating in colder climates.[1]

The US Department of Energy (DOE) provides analysis of overall US building energy consumption by end use. This data is not separated by building type, envelope, function, or location, but it is useful in that it shows that 50% of US building energy use goes to mechanical systems (heating, cooling, and ventilation) and 9% goes to lighting. The DOE’s data also shows that the average energy use intensity (EUI) for buildings pre-1959 through 1969 was 71.4 to 75.5 kBtu/ft2/yr, whereas the EUI for buildings constructed in 2000 through 2009 was 81.4 kBtu/ft2/yr. Also, the energy cost for office buildings constructed pre-1959 to 1969 was $2.50/ft2, whereas the energy cost for buildings constructed in 2000 through 2009 was $2.10/ft2.[2] This data shows that the energy performance of older and newer office buildings is roughly equal.

Evaluating building energy use’s impact on the environment should include the energy used to extract, generate, transport, and transmit energy to the building (source energy), not just the building’s EUI. These processes affect energy’s pricing, which includes the costs of the source energy and the energy that the building uses. Therefore, the building’s energy cost can better indicate the building’s energy impact on the environment. Since electrical efficiency will vary by generation type (e.g., hydroelectric plant vs. coal-fired plant), energy cost data helps evaluate energy impacts. However, the correlation between total energy and energy costs are not always direct; demand schedules, market forces, government subsidies, etc. also affect energy costs. Also, building owners typically base improvements on the building’s energy costs, not energy use, being more concerned with the return on investment (ROI) for such upgrades. Consequently, we consider energy costs to be the main practical consideration in these analyses.

2. Energy Modeling and Analysis

We created energy models of two buildings: a four-story building and a twenty-story building, both in New York, NY (NYC, mixed climate). The four-story building is mid-block with adjacent buildings on two sides and the twenty-story building is standalone. This exercise was theoretical to test potential energy improvements, not an analysis of specific existing buildings. Our objective was to evaluate the relative change in energy performance and cost from incremental improvements to the building envelope and mechanical systems. We also modelled a contemporary curtain wall building with modern envelope and mechanical systems. We used DesignBuilder Version 3.2.0.067 and EnergyPlus Version 7.2.0.006 for our modeling.

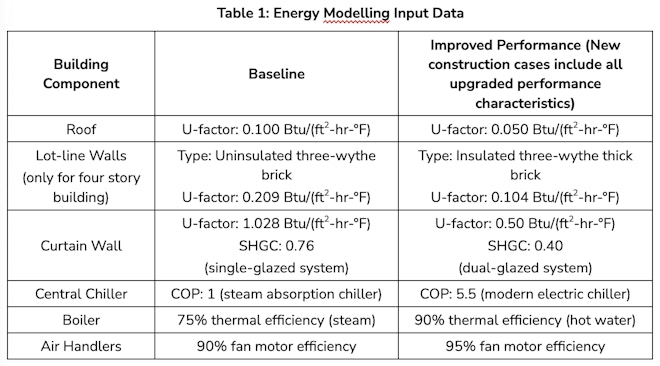

Table 1 lists the building components that varied between models, which we based on experience with mid-century and contemporary curtain wall buildings and on 2011 NYC energy code requirements for new buildings. The mechanical systems include a central chiller plant, a central boiler plant; constant volume ventilation and cooling, and steam radiators with forced air in each zone.

Table 1: Energy Modelling Input Data

1.1 Four-story Building

Our analysis showed that the baseline four-story existing curtain wall building had a simulated EUI of 147 kBtu/ft2/yr, which matches data published by the Lawrence Berkeley National Laboratory (LBNL) for older US office buildings.[3] Most e energy was for heating at 59%, with 14% for cooling and 9% each for lighting and ventilation. However, when modeling energy costs (using New York energy cost data [4]), cooling had the highest percentage cost at 26%, with 20% for heating and 18% each for lighting and ventilation. The systems that use electricity (cooling, lighting, and ventilation) have higher energy cost due to energy use and losses from generation and transmission.

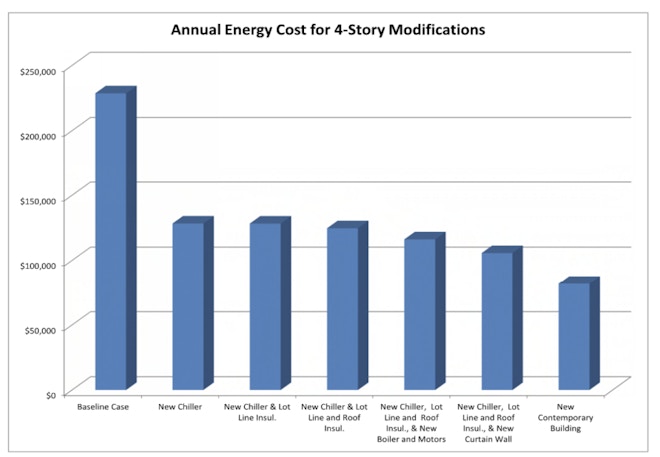

We reviewed the following upgrades to the envelope and mechanical systems (listed in order) (Fig. 1):

Replacing the chiller with a modern chiller reduced annual energy (operating) costs approximately 45%.

Adding insulation to the lot-line walls and roof had negligible effect.

Replacing the steam boiler and radiator system with a modern hot water system and new fan motors reduced energy costs approximately 7%.

Replacing the curtain wall with a modern system, but maintaining the existing boiler and fans, reduced energy costs approximately 15%.

Figure 1. Effects of Upgrades to Building and Systems on Energy Costs for the Four-Story Building

The models showed that replacing the chiller with a modern chiller has the greatest effect on the energy costs. In comparison, a new curtain wall building has energy costs 36% lower than replacing only the chiller in an existing building. However, considering the construction costs and energy required to demolish the existing and construct a new building, replacing a chiller would have a much lower initial cost, faster ROI, and much lower impact on the environment. Other incremental improvements could further reduce the energy cost but likely would have much longer ROI.

The models also showed that replacing the existing curtain wall with new would have relatively low effect on the building’s energy profile after replacing the chiller. But again, we expect that replacing the curtain wall would have more impact on the environment, not to mention the loss of historic fabric.

1.2 Twenty-story Building

Our analysis showed that the baseline twenty-story curtain wall building had an EUI of 150 kBTU/ft2/yr, which again matches data published by the LBNL.[3] The majority of the energy consumption was for cooling at 59%, with 14% for ventilation, 10% for lighting, and 8% for heating. The energy costs (using New York State energy cost data[4]) follow the energy consumption, with 64% for cooling, 15% for ventilation, 10% for lighting, and 1% for heating.

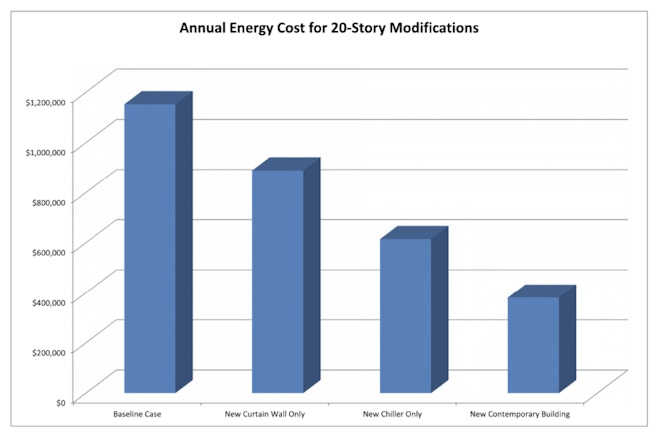

We reviewed upgrades to the building and its equipment, which we list in order here (Fig. 2):

Replacing the curtain wall with a modern system reduced energy costs approximately 23%.

Replacing the chiller with a modern chiller, but maintaining the existing curtain wall, reduced annual energy costs approximately 47%.

Figure 2. Effects of Upgrades to Building and Systems on Energy Costs for the Twenty-Story Building

The models showed that replacing the chiller alone can reduce the energy cost almost by half and that it has a much greater effect on the building’s energy profile than replacing the curtain wall, likely at much lower cost and impact on the environment. While the 23% savings in energy cost from replacing the curtain wall is significant, it is half of the savings resulting from replacing the chiller.

When comparing upgrades to the existing building to a new building, a new building would have energy cost 38% lower than replacing the chiller only, but at a much higher initial cost and we expect a far greater impact on the environment.

3. Conclusion

For the types of buildings in climates similar to our models, replacing historic curtain wall systems with modern systems likely will not result in as significant an ROI as other potential improvements. While the performance of the envelope will affect the mechanical systems’ demand (a better-performing envelope will place lower demand on the mechanical systems), in our models the older mechanical systems’ efficiencies have more effect on the buildings’ energy profile than the curtain wall, and for taller buildings the curtain wall has less effect on energy. The greatest ROI in these cases is to replace older cooling equipment with more efficient equipment. Note that the results of this type of modelling will vary depending on location, exposure, and specific building systems.

Several cities are evaluating older commercial buildings for potential conversion to residential as a way to increase housing stock but reduce the environmental impact of doing so. Energy codes often require the building enclosure to be upgraded with these conversions. Given that the mechanical systems likely would require complete replacement, this study shows that the overall energy performance of the building may be “good enough” with the existing older curtain wall in place when the embodied energy of both the existing curtain wall and a new curtain wall is taken into account.

4. References

- [1] P. Oldfield, D. Trabucco, and A. Wood. “Five Generations of Tall Buildings: An Historical Analysis of Energy Consumption in High Rise Buildings,” The Journal of Architecture vol. 14 (5), pp. 591-613, 2009.

- [2] US Department of Energy. (2012, March) 2011 Buildings Energy Data Book. [Book]. Available: http://buildingsdatabook.eere.... [30 July 2014]. Note, data in the original are in English units and US dollars. We converted to metric units and Euros for this article.

- [3] Lawrence Berkeley National Laboratory. “Building Performance Database.” Internet: https://bpd.lbl.gov/ [October 2014]. Note, data in the original are in English units. We converted to metric units for this article.

- [4] US Energy Information Administration. “U.S. States State Profiles and Energy Estimates.” Internet: http://www.eia.gov/state/seds/ [October 2014].

* This is an excerpt from the following article:

Artigas, D., S. O’Brien, and A. Aijazi. “An unfair reputation: The energy performance of mid-century metal and glass curtain walls.” In Conference Report, The 3rd International Conference on Energy Efficiency in Historic Buildings, edited by Tor Broström, Lisa Nilsen, and Susanna Carlsten, 391-400. Visby, Sweden: Uppsala University, Department of Art History, 2018.

David Artigas, P.E.

David Artigas, P.E., is a Senior Project Manager at Simpson Gumpertz & Heger, Inc. He manages the investigation, design, and construction administration of building enclosures on both historic and contemporary buildings of many types in the United States. He also performs thermal and hygrothermal modeling and assessment of building enclosure assemblies, specializing in existing and historic building enclosure systems.

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.