View StudioTJOA’s complete design submission for the Thermalswitch Facade.

Q&A with StudioTJOA, Creator of the Award Winning Thermalswitch Facade

In 1963, 200 Park Avenue opened in midtown Manhattan as the world’s largest commercial office space. While its place in the urban environment is less authoritative today (it’s ranks just outside of the 50 tallest buildings in the United States alone), it stands alongside many of its mid-century peers — those designed by the likes of Philip Johnson, I.M. Pei, Mies van der Rohe, and Eero Saarinen — as a monument to post-war innovation. As the pendulum continues to swing between the desire to preserve buildings of historical significance and the energy efficient frenzy of the 21st century, 200 Park Avenue remains a poignant example of unsustainable modernist architecture.

Inspired by the President’s Climate Action Plan and Architecture 2030 Challenge, Metals in Construction magazine and the Ornamental Metal Institute of New York tapped designers in late 2015 to create an eco‐friendly, highly transparent enclosure that preserves the aesthetic integrity of 200 Park Avenue. Emerging from the submissions by industry heavyweights was StudioTJOA, the firm of husband and wife duo Alex and Audrey Worden in Boulder, Colorado. Last month the pair walked away with one of six awards for an overclad system that combines passive design strategies and dynamic components called the Thermalswitch Facade.

FTI: Walk us through the design of Thermalswitch, and why you chose to pursue an overclad strategy.

StudioTJOA: We started by researching the original 1960s design and construction methods to distill the building envelope into its critical elements. We then ran a baseline thermal analyses of the existing precast system to confirm that overcladding was the most effective means to simultaneously reduce thermal bridging across the existing units and maintain the building’s textural aesthetic.

FTI: Speaking strictly to the historical preservation component of the competition, how did your ideas evolve?

StudioTJOA: One of our initial approaches included a large, double-skin cavity that spanned a number of floors and terminated at exterior gardens, for example. But doing so presented a number of challenges. First, we would have to demolish portions of the facade to hang the secondary structure for the new units. Second, the vertical fire separation was going to be more difficult, especially if we were planning to draw in air from a double-skin cavity. After several more iterations, we decided that a simple floor-to-floor spanning unitized system was the most efficient way to retain the preservation component and also achieve our performance goals.

FTI: An overclad design also creates an opportunity for an interstitial cavity between the new and existing facade, which can go many directions in terms of performance gains.

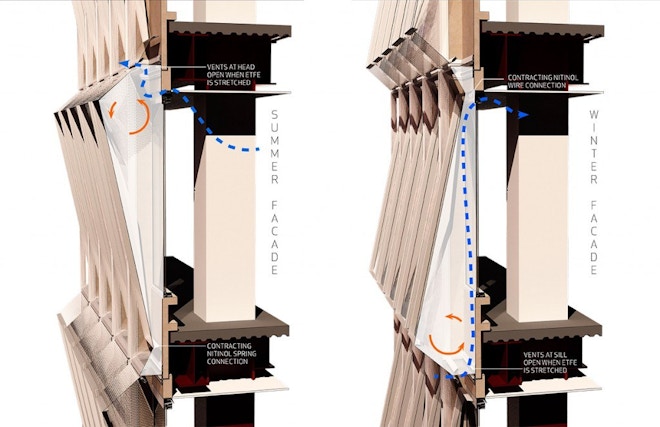

StudioTJOA: Exactly. From the start, we had the idea of creating a unitized Trombe wall that would allow the envelope to “breathe” by changing with temperature and regulate the interior environment. Traditionally, Trombe walls are used to passively heat, however New York is cooling load dominant, so we set out to develop a way for the system to adjust with the seasons. As we sketched through ideas of how to increase airflow in the building, it became clear that the facade was going to have to move with the changing temperatures. From here we began experimenting with different tilting geometries to maximize sun shading in the summer and solar gain in the winter.

FTI: So how does the unit actually move in response to New York’s Climate Zone 4 requirements?

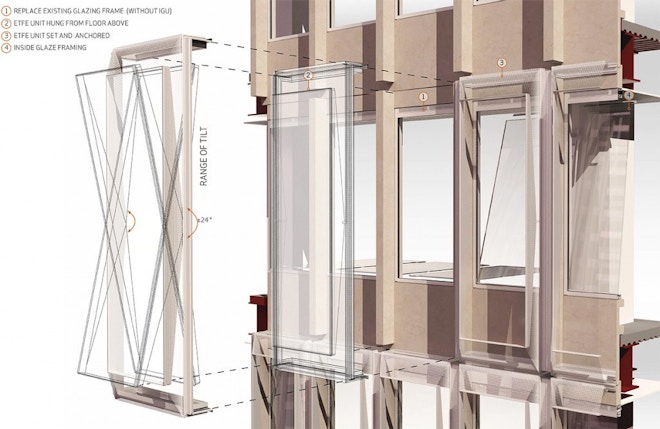

TJOA: After a number of geometric studies, we found that a hinged frame allowed for the greatest variance: 24 degrees from vertical. By attaching a spring at the top of the unit and a bimetal (nitinol) cable at the bottom, the frame could tilt slowly, passively, and in response to the ambient temperature of the interstitial cavity.

FTI: Which leads us to one of the system’s most important contributions to the energy efficiency prerequisite: air intake.

StudioTJOA: The ability to circulate fresh, preconditioned air throughout the building without the dependency on traditional air conditioning and mechanical equipment is Thermalswitch’s largest performance contribution. By utilizing the kinetic action to create isolated convention currents, the envelope is able to draw air passively through the facade and cool building occupants. We understand that this might be a utopian view, so this passive airflow could be assisted by pressurizing the building. In the summer, the building would be positively pressurized so that the cooler air within its core would be drawn out through the facade, creating a cool draft and using the core as a geothermal trunk. In the winter, pressurization would be reversed so that fresh air is heated in the double-skin cavity and pulled in through trickle vents at each floor.

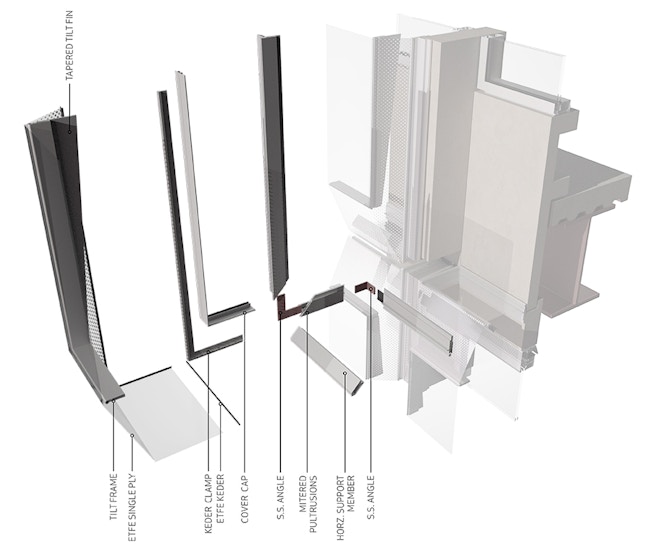

FTI: Material-wise, how do you accommodate the movement of the frame?

AW: We chose ETFE, a flourine based polymer, as the cladding material for a number of reasons. In a single ply membrane application, it gives us the freedom to explore a moving system without greatly affecting the overall light transmittance into the building. All our geometric explorations were coupled with daylighting studies to verify this. Even in the most shaded condition, for example, the daylight factor does not fall below minimum code requirements. In the end, it was the ETFE’s relative elasticity that dictated the frame’s maximum tilt.

FTI: Is there a potential for conductivity with the unitized frame?

AW: We looked at alternatives to traditional aluminum framing because the units are mounted on the existing precast facade. By using fiberglass pultrusions, we could minimize thermal bridging across the system and reduce the possibility of the convection currents in the interstitial cavity from short-circuiting.

FT: Lets talk constructability. One of the primary concerns with retrofitting commercial space is if the building will remain operational throughout construction. How does Thermalswitch Facade address this?

TJOA: The Thermalswitch unit hangs off the existing facade similar to drop and lock shelves or pegboards found in workshops, so the idea of flying units from the ground via some sort of crane just doesn’t make sense. Our proposal is to floor load the units, slide them out through the existing facade openings after removal of the existing glazed frames, and then install them on the floor below. By doing so, only two floors have to be occupied by construction crews at a time: the loaded floor (A) and setting floor (B). The loaded floor would include a custom floor crane to allow the unit to slide horizontally out of the facade (laying on its long edge), and then lowered to the setting floor below. Once a setting floor is complete, both crews would proceed to the floor above. This method of installation limits disruption during the overcladding process while being sympathetic to the fiscal aspects of such an endeavor.

FT: What maintenance considerations were given to the system?

AW: The system’s simplicity makes it relatively maintenance free. By utilizing the hinged frame and Nitinol cable system, the Thermalswitch Facade acts as a self-regulating pivot frame without the addition of a complex system or electricity. Every building owner wants to hear that, right?

Matt Elder is a Senior Communications & Marketing Specialist at Enclos. From 2012-2015, he served as Co-Coordinator of the Facades+ conference series. His writing and photography has been published extensively by Enclos, in addition to The Architect’s Newspaper, Bike Magazine, Engineering News-Record, Filter Music Magazine, and Guitar Player Magazine.

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.