Next normal: Advanced composites for a changing industry

As the 2020 McKinsey & Company report “The Next Normal in Construction” points out, change is coming fast to the construction industry. From designers and engineers to subcontractors and material suppliers; agility, and a relentless awareness of our surroundings is the only real survival mechanism. “Companies can try to defend their positions and adjust to the changing environment or reinvent themselves to take advantage of changes in the industry.”

We’ve all heard how our industries’ productivity has lagged far behind other industries. The construction ecosystem represents 13% of global GDP but productivity has grown a meager 1% annually for the last two decades, a fraction of the productivity growth of other industries with the same tools available to us as to them. Meanwhile, demand continues to grow. McKinsey predicts that over $69 trillion in global infrastructure will be needed by 2035. Skilled labor is in short supply. Forty one percent of the current US construction workforce will retire by 2031. Despite the construction industry's aversion to risk, change will happen. Being aware of these changes and adapting will differentiate the winners from the losers.

McKinsey goes on to suggest that 9 “shifts” will radically change the way construction projects are delivered. These include digitization of products and processes, industrialization, specialization, value-chain control, consolidation, customer-centricity and branding, investment in technology and facilities, investment in human resources, internationalization, and sustainability. There is, however, one more on their list: new materials. The topic of this issue of SKINS focuses on the impact of one such “new” material and how it might impact building envelopes.

Modern chemistry, analytics, material science, and other disciplines are causing an avalanche of new materials available to our industry. One of those, and one that has brought disruption to several other industries including the marine, transportation, aerospace, sports and recreation industries, is commonly referred to as “advanced composites”. Advanced composites—or composites, a term we’ll use throughout this issue, is a family of materials that take the “string and glue” principle utilized in Neolithic times with straw and clay, or more recently with steel and concrete, to a new family of highly refined materials made by combining natural or manmade fibers with synthetic resins.

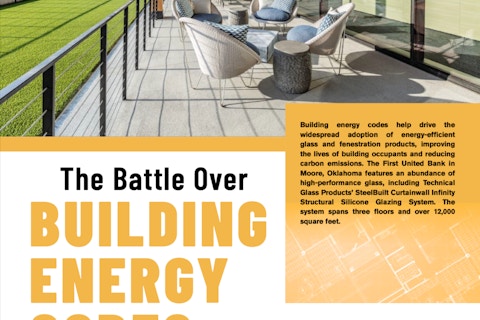

The SFMOMA FRP facade is reportedly one of the first and largest applications of FRP in the building facade.

The resulting products have remarkable properties which, when applied to something like a building façade, can provide dramatic new potential for design, engineering, sustainability, and assembly costs. But, as with all new ideas or products, early adapters need to exercise caution; composites are not simple systems. They are different from other materials in many ways. Designers, specifiers and end users who don’t recognize the potential for misuse, or who take on face value claims lacking an appropriate basis in fact, can find themselves in some difficulty. While composites may offer significant advantages over traditional materials, the process does not easily accommodate changes mid-stream. Once you’ve started down the path of implementation it can be a challenge to turn back. Still, the path can yield amazing results. The well-informed designer can provide clients better, more environmentally efficient, more beautiful and often more cost-effective solutions.

This issue of SKINS will attempt to introduce you to composite materials in an accurate, useful and fairly in-depth way. But it’s only an introduction; it’s a start but by no means a rigorous exploration of the full potential of this remarkable material technology. Hopefully, it will answer some questions, offer some useful information, and reveal some of the reasons composite materials will become increasingly utilized on building facades as they become more widely understood and accepted. Most of all, we hope to inspire designers to unlock and explore the full potential of this material in building applications.

Kurt Jordan will explain engineering principles that can better exploit composite advantages. Shajay Bhooshan will talk about shape and its relevance to not only aesthetics but constructability and overall building efficiency. Nick Dempsey will clear up some questions about fire resistance, and Mike Lepech will discuss environmental issues. This is the tip of the iceberg on a vast and often complex and confusing subject, but you are hearing from thought-leaders in their field. I want to express my deep appreciation to these authors, my friends, for their insightful and valuable contributions to this issue of SKINS. If you find this issue worthwhile, maybe the SKINS editorial team and my friends at the Facade Tectonics Institute will invite me back someday for Composites 102!

Let us know what you think! You can reach us at skins@facadetecontics.org.

Best regards to all,

Bill Kreysler, Kreysler Associates

President

Napa, CA; August, 2021

Guest Editor

Great thanks to our guest editors from all of us at

The SKINS Team:

Mic Patterson, Facade Tectonics Institute

Executive Editor

Val Block, Kuraray

Associate Editor

Brienna Rust, SGH

Christopher Payne, Gensler

Content Editors

Nick Carrillo, WWCCA

Event Calendar Editor

Alberto Alarcon, Kuraray

Event Calendar Editor

William Kreysler

President

Kreysler & Associates

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.