Material Matters: Embodied Carbon Considerations Impacting Design Practices for Facade Systems, Buildings, and Urban Habitat

The building sector as a primary contributor to anthropogenic climate change. Carbon emissions from the U.S. building sector are anywhere from 40-50% (depending on who you listen to) of total carbon emissions. The awareness of the problem of fossil fuel consumption in the built environment emerged gradually in the years following the energy crisis in the latter half of the twentieth century. A focus on energy efficiency of new buildings has persisted since that time. Progress in this area over the years has shifted some attention now to the problems and opportunities represented by the existing building stock, and also to the issue of materiality and embodied energy—the theme of this month’s edition of SKINS. The conventional assumption for many years has been that the embodied portion of a building’s lifecycle energy footprint is approximately 10% or less, so can be generally ignored in favor of addressing energy efficiency improvements during a building’s operational cycle. A growing body of research challenges the validity of this assumption with significantly higher percentages of embodied impacts over a building’s lifecycle.

Paula Melton’s article for BuildingGreen (featured in this issue of SKINS) on the urgency of embodied carbon provides a great general introduction to the topic.

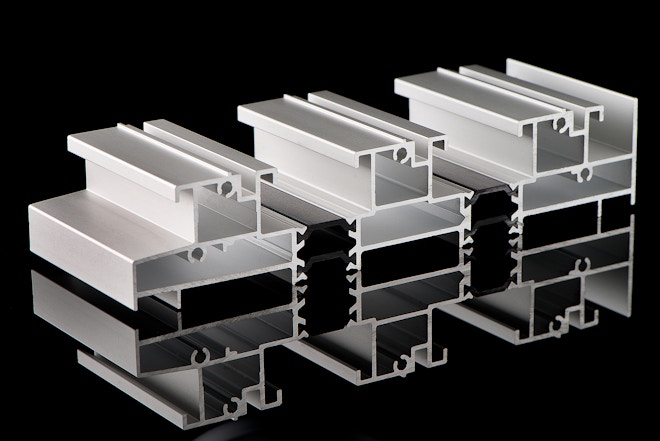

Reducing the greenhouse gas (GHG) emissions produced by building operations remains a clear priority, but there is a growing realization that we have been improving operational energy efficiencies by shifting lifecycle impacts to the embodied side of the carbon equation without quantifying or accounting for the shift. This is simplistically exemplified by the typical double-skin strategy of adding another layer of glass to the building skin. Operational carbon emissions are cut and we talk about “high-performance” facade systems. But this is a false economy if we are ignoring the embodied carbon footprint of the additional materials, which offset, sometimes significantly, the operational carbon performance gains. Craig Jones with Circular Ecology provides a study showing that the added embodied carbon in moving from a double-glazed to triple-glazed IGU may require 20 years of operational carbon savings to offset; basically, the service life of the IGU. Any shorter lifespan would result in a net loss. Yikes, yeah?!

It turns out, according to the United Nations Environment Program, that the manufacture of building materials makes up 11% of global greenhouse gas emissions. Carbon emissions from buildings total 39% of global GHG emissions, with 28% of that being embodied carbon, far greater than the 10% or less commonly assumed. (Studies of individual buildings have shown far higher percentages of embodied carbon.)

The materials, products, components and finishes we use in buildings and building assemblies arrive at the building site with a carbon debt resulting from material extraction, cycles of processing and manufacture, equipment operation, related transportation of materials and workers; everything that was required to produce the material or product and deliver it to the building site. This we call embodied carbon. The aggregate carbon debt of all required materials is then increased by the carbon emissions produced during the construction cycle. So, a building begins its operational cycle with a significant carbon debt. (Maintenance and renovation activities during the operational phase and end-of-life activities including reuse, recycling and disposal, also add to the embodied component of a building’s lifecycle carbon footprint.)

Embodied carbon considerations amplify the time value of carbon and the critical importance of early carbon reductions to meet the goals of the 2015 Paris Climate Accord: zero carbon by 2050 as a strategy to limit global temperature rise. Spoiler alert: Cutting to the chase on embodied carbon reveals the fundamental truth that we should, at this time of acute need for carbon emission reductions, be building as little as possible. That’s a tough sell in today’s marketplace and, perhaps sadly, not a realistic proposition. Settle for the primary take-away of using materials with a low embodied carbon profile (e.g., virgin aluminum is highly energy intensive in its manufacture whereas wood is typically far less so), high recycled content, and using as little of it as possible.

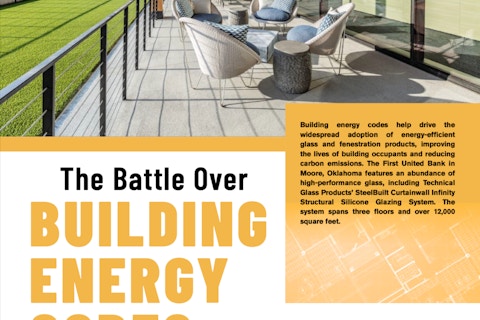

Aluminum and glass, predominant components in the building skin, are both high embodied carbon materials. Melton notes the heavy embodied carbon footprint of curtainwall and calls for limiting its use. Unless ways are found to reduce the carbon footprint of these systems, restrictions on their use are ultimately unavoidable. One of the most effective means of minimizing the lifecycle embodied carbon footprint of a building system is to extend its service life. This consideration brings to the fore such unfamiliar and challenging concepts as durability, adaptability, maintainability, upgradability, repairability, reusability; what I’ve come to call the ‘abilities, or in the case of the facade system, the (dis)-abilities. Embracing the (dis)-abilities will drive step-change—with disruptive potential—in facade system design and delivery. Melton only briefly discusses the end-of-life considerations that can dramatically impact lifecycle embodied carbon. This is an area we intend to tear into at Facade Tectonics, so become a member supporter of the Institute and join the dialogue!

The embodied carbon consideration is surging in awareness within the building marketplace and is changing the way we are thinking about building practices across the board. The Facade Tectonics Institute is taking this issue on the road in its FTI Forums programs for 2019, full-day events to be held in Miami (March 22), Minneapolis (April 15), Toronto (May 3), Seattle (July 16), and Houston (October 10).

Mic Patterson, PhD, LEED AP BD+C

Ambassador of Innovation and Collaboration

Facade Tectonics Institute

Send Email

Mic Patterson is a designer, researcher, educator, futurist, author, photographer and entrepreneur. He has concentrated his professional and academic career on advanced facade technology and sustainable building practices. He pioneered the introduction of structural glass facade technology in the United States in the 1990s, implementing diverse and novel applications including cable trusses, cable nets and grid shells. Patterson was among the founding group of the Advanced Technology Studio of Enclos, where he works as the Vice President of Strategic Development. He is a co-founder of the Facade Tectonics Institute and serves on the steering committee, and co-founder of the Facades+ conference series. He is on the technical research committee for GlassCon Global and a member of the Advisor Group for the Council for Tall Buildings and Urban Habitat. He has twice been named among the industry’s most influential by US Glass magazine. Patterson is a Ph.D. candidate in the School of Architecture at the University of Southern California with a research focus on sustainable facade renovation practices. He has taught, written extensively, and lectured internationally on diverse aspects of advanced facade technology. He is the author of Structural Glass Facades and Enclosures, published by Wiley.

Publisher’s note: The views expressed here are those of the author, and do not necessarily reflect those of, nor are they endorsed by, the Facade Tectonics Institute.

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.