Share your thoughts; you are encouraged to contribute your own insights and considerations! Send them to me at mpatterson@facadetectonics.org.

Beyond Glass (literally or metaphorically): Trends, drivers, and future trajectories

The following is derived from a Request for Proposal for speakers in an experimental program session for Facade Tectonics Forum: VANCOUVER to be conducted Monday, 30 July 2018. Speakers include Stéphane Hoffman with Morrison Hershfield, Hamid Vossoughi with WSP, and Dr. Chris Drew with AS+GG Architects.

“Beyond Glass” can be interpreted in various ways.

1. Anticipating the trajectory of future development in architectural glass technology.

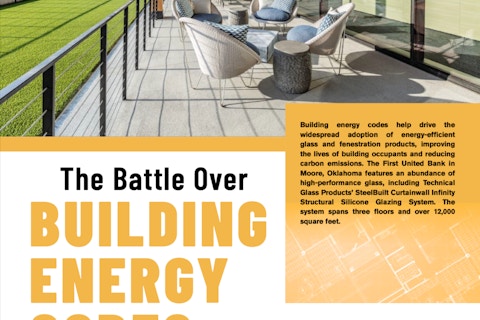

Michael Bell posited in his book Engineered Transparency that contemporary “glass is not glass,” referencing the condition that today’s highly engineered architectural glass products bear little resemblance to the raw product produced through the float process as initially used in single-glazed applications starting in the 1960s. The secondary processing of float glass—developed in response to the inherent weaknesses and problematic behavior of glass in architectural applications—poor thermal and acoustical insulator, solar transmittance, brittleness and breakage behavior—involving heat treating, coating, laminating, and the subsequent use of these materials in increasingly complex assemblies as insulated, laminated, photovoltaic, electrochromic and other diverse products, has far outstripped the value of the global float production output (Figure 1). Where is this trajectory headed? This is, perhaps, the most obvious trajectory for considering “beyond glass,” and indeed, the glass industry has a remarkable track record of delivering increasingly higher performing products over past decades. But how much more in the way of performance enhancements can be provided by spectrally selective and low-e coatings? Diminishing returns negate the value of quadruple over triple silver. Vacuum glazing has been an industry promise for years, yet an economically viable product at scale remains unrealized. Efficient PV vision glass has been the long-term pursuit of a dozen R&D programs with little in the way of practical results for facade-integrated applications. Decades of industry effort to produce market-viable electrochromic technology has finally resulted in the availability of product options struggling for adoption in a market ruled by first-cost considerations. Perhaps these trends indicate that, barring the development of radical breakthrough technology, we are near the limits of performance enhancements in architectural glass products. Perhaps this signals the need to look “beyond glass” as an architectural product to the assemblies of which it is a component part, as the pathway to future development.

2. Anticipating the trajectory of future development in facade assemblies.

The focus has long been on the glass in facade system performance. It is now recognized that the framing systems play a significant performative role, and that it is the performance of the assembly that must be evaluated (Figure 2). Little has changed in curtainwall technology since its inception in the mid twentieth century. One can speculate that the industry is ripe for disruptive change.

Scott Thomsen, former president of the Global Glass Group for Guardian IndustriesThe glass industry is mired in incrementalism. Industries die if they don’t make large changes. Industries fail without a major step change every 30 years.

There are certainly issues. Aluminum as the predominant framing material is an unfortunately efficient thermal conductor. Thermal breaks can be effective if executed properly yet add considerably to system complexity and cost. The lack of ‘abilities—maintainability, repairability, upgradability and adaptability—in curtainwall system designs has compromised durability and produced a growing number of early curtainwall buildings in need of retrofit, with the lack of viable options often necessitating the complete removal and replacement of the facade system, at great cost to the building owner and disruption to the building occupants. This problem is exacerbated by the premature service life termination (for reasons ranging from technical obsolescence to the disharmonious service life characteristics of IGUs) of the highly durable glass and aluminum components of the system, both high embodied carbon materials, contributing to an enlarged lifecycle carbon footprint for the building. The root problem here is the failure of these early curtainwall systems to properly account for an appropriate service life in their design. This problem, however, is equally true of today’s curtainwall system designs, creating the very real probability that we are busy building tomorrow’s problems today. So, how long should a facade system last? How long should a building last? What are the implications of longer service life on facade system design.

3. The future trajectory of transparency in the building skin.

Much in building and facade system design has resulted from the pursuit of transparency in the building skin (Figure 3). Architects want minimal sight lines. Occupants want floor-to-ceiling glass; the corner office with two all-glass walls is aspired to by business executives as a symbol of accomplishment. This demand continues to produce buildings with significantly compromised performance, a trend on a collision course with escalating code requirements driven by the need to significantly reduce carbon emissions in the building sector. Building scientists have pointed to the fallibility of the tall glass building (Can highly glazed building facades be green? – John Straube; Lstiburek, others). Will the trend of maximal transparency finally yield to the critical need for improved performance? Will opacity, with its opportunities for enhanced thermal and acoustical behavior, be embraced, even reluctantly, as a pathway to performance? Recent projects that have embraced these constraints, like the tallest building constructed to Passive House standards designed by Handel Architects for Cornell University on Roosevelt Island, clearly display an increase in opacity over their contemporaries cropping up over New York City. The glass industry vigorously fights the “war of the wall”—attempts to prescriptively reduce the window-to-wall ratio or otherwise restrict the amount of allowable facade glazing—arguing the health and wellness attributes of glass in providing daylight to the interior and visual connection to the outdoors. If glass is good, is more necessarily better? How much glass is enough glass? If opacity becomes the trend, what does that look like, what form does it take, from facade system design to the future of super-insulated opaque panel? Many lines of inquiry suggested by this consideration.

4. Timber as a facade material.

Although an increase in the building skin material palette has been trending over recent years, glass and aluminum remain the predominant materials. Both are high carbon intensity materials. Timber is trending strongly as mass-timber framing in increasingly taller building applications. Wood has the primary advantage of a lower embodied carbon profile in its manufacture, plus it sequesters carbon over its lifespan, that is until it combusts or decomposes, thereby actually pulling carbon from the atmosphere and storing it. But wood seems a poor facade material because of its weathering properties, especially in high-rise applications where access for maintenance is challenging. Is there potential for timber as a facade system material? What does its use suggest in terms of facade system design?

5. Thin skins vs. thick skins.

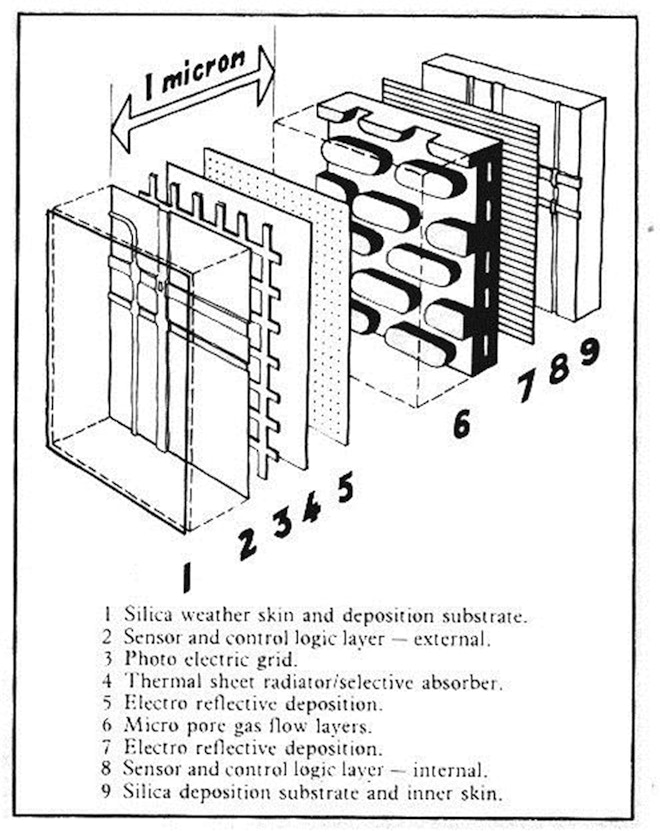

These can be looked at as divergent trends. On one hand is the effort to pack performance technology into the 1-inch thickness of the conventional insulated glass unit (IGU); how much more can be accomplished? The availability of an economically viable insulated glazing could potentially dramatically improve the performance of an IGU. Nonetheless, the depth imposes a limitation, and conventional IGUs are problematic in important respects. The bonded assemblies of coated glass are unfit for recycling, at least with today’s fabrication practices, resulting in most replaced glass ending its lifespan as landfill. In addition, the assembly effectively collapses the service life of the float glass from indefinite (100s of years) to 20-30 years, an unfortunate consequence with respect to a high embodied-carbon material like glass. The counter-trend amounts to a redefinition of the facade zone that renders it challenging to define precisely where the facade system begins and ends. This is partially rooted in Mike Davies polyvalent facade concept (1981) where functionality is parceled into distinct layers (Figure 4). This suggests an alternate strategy to the IGU, where the function of solar coatings, for example, are provided by a layer of shading. The discrete layers can more easily be designed for maintainability, adaptability and recyclability. Some double-skin designs expand the facade depth to accommodate shading and maintenance systems, and some, like the Shanghai Tower by Gensler, even incorporate public and circulation space (Figure 5). Consideration must be given, however, to the embodied carbon impacts of increased facade system materiality. Emerging considerations of embodied carbon and the “time value” of carbon are revealing that solving performance problems through the addition of large quantities of high embodied carbon materials may be false carbon economy, indeed.

6. Other trajectories in the spirit of beyond glass?

Mic Patterson, PhD, LEED AP BD+C

Ambassador of Innovation and Collaboration

Facade Tectonics Institute

Send Email

Mic Patterson is a designer, researcher, educator, futurist, author, photographer and entrepreneur. He has concentrated his professional and academic career on advanced facade technology and sustainable building practices. He pioneered the introduction of structural glass facade technology in the United States in the 1990s, implementing diverse and novel applications including cable trusses, cable nets and grid shells. Patterson was among the founding group of the Advanced Technology Studio of Enclos, where he works as the Vice President of Strategic Development. He is a co-founder of the Facade Tectonics Institute and serves on the steering committee, and co-founder of the Facades+ conference series. He is on the technical research committee for GlassCon Global and a member of the Advisor Group for the Council for Tall Buildings and Urban Habitat. He has twice been named among the industry’s most influential by US Glass magazine. Patterson is a Ph.D. candidate in the School of Architecture at the University of Southern California with a research focus on sustainable facade renovation practices. He has taught, written extensively, and lectured internationally on diverse aspects of advanced facade technology. He is the author of Structural Glass Facades and Enclosures, published by Wiley.

Publisher’s note: The views expressed here are those of the author, and do not necessarily reflect those of, nor are they endorsed by, the Facade Tectonics Institute.

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.