Patchwork

How Textile Techniques Generated the First Enclosures, Coded Complex Machines, and Influence Space, Form, and Structure in the Digital Age

Sign in and Register

Create an Account

Overview

Abstract

It may be difficult for modern man to believe that what is known as handicraft was once the advanced manufacturing of the day. These techniques were used to create the first garments and portable shelters. There is much speculation as to their origin. However, the common thread in early enclosures is skin. Whether hides or woven surfaces, this cladding adorned the human form for warmth and then evolved into the first to enclose space and delineate interior from exterior. From these noble beginnings, the built environment of today is a global village of brick, glass, and metal. However, all methods of construction are steeped in these early traditions of fabrication.

Many of the advancements of the world today trace back to the textile techniques of early man. Beyond the realm of handicrafts and pastimes, fiber techniques continue to generate complex concepts and forms. From the punch cards of the jacquard loom to the first read-only memory used in the Apollo space missions, the sheer breadth and variety of these examples express textiles’ deep influence in process and result.

With the increase in digital technologies and the rapid manufacturing of modern autonomous machines, traditional indigenous structures and fabrication techniques can easily be seen as outdated in comparison. However, simply because these digital tools and techniques exist, does not mean that traditional techniques cannot be used in new ways to aid or influence the design, development and fabrication of the built environment. In fact, it should be just the opposite.

Throughout history, designers have seen the benefits of exploring and playing with these early fabrication techniques previously seen as pastimes of folk art. However, by leveraging these handicraft methodologies, it enables a seamless balance of old and new technologies to augment each other, effectively marrying early fabrication techniques with those of the digital era. From fibrous loops to weaving of walls, these fabrication techniques have heavily influenced many facets of the built environment in the 21st century.

Authors

Alexander G. Worden, AIA

Studio NYL

aworden@studionyl.com

Keywords

Introduction

“We shape our tools and our tools shape us.” – Marshal McLuhan

In the 21st century, humanity finds itself split between two environments — the physical reality described by our senses and the digital realm where the laws of physics are suspended and materiality consists of zeros and ones. This paradigm is no different from that of any other new technology. Upon its advent and integration into the rigors of everyday life, the exploitation of new tools is without restraint or justification; it is progress for the sake of progress. However, as new technologies become more commonplace, novelty cools and a shift occurs. Questions arise — how does this tool help? When does one utilize it? Moreover, what is its effect? It is critical to attempt to understand how any tool is most efficiently utilized while understanding the feedback loop effect on the human mind and society as a whole.

It is difficult to imagine that this pattern occurs with any technology, even the primitive techniques of early humans. Ultimately, any technological addition changes the group and the overall environment. Early techniques in pottery, carpentry, but specifically textiles are perfect examples of how even the simplest of techniques radically change the course of a people. These early methods of shaping material gave rise to clothing, nets, animal pens, and ultimately the first structures. As there are no records of how these all came to be, many have hypothesized their origins. But the most notable are those proposed by Gottfried Semper. His theories in textiles are still prominent to this day due to their deep insights into how man perceives nature and how he manipulates materials into functional and artistic products.

From the hearth and mound to the roof and enclosure, the process of developing structures, at its core, has remained relatively unchanged, and it could be argued that today’s buildings are, elementally, no different from that of early peoples’. Regardless of the tools of the day, it is material and method that generate the essential elements of the built environment. However, beyond the function and aesthetic, there must be a desire to understand the importance of when to use a tool, how it affects the process, and when it is to be implemented. There is no better tool or technique than that of textiles as it predates history and has continued to evolve alongside man throughout the ages.

These surfaces of woven, knotted, looped threads create some of the most intricate works that are as aesthetically pleasing as they are functional. From early fishing nets and loincloths, to the complex textile machines of the industrial revolution and the development of early computing, these base textile techniques have been behind the creation of many historical achievements. Because of this continuity, textiles are the perfect vehicle to better approach and understand the burgeoning digital environment and its machines. By blending materiality and process of rule-based production, these pliant modes of fabrication can aid in the play between the digital and physical environments, forms, surfaces, and structures before man is lost within them.

Background: Brief History of Textile

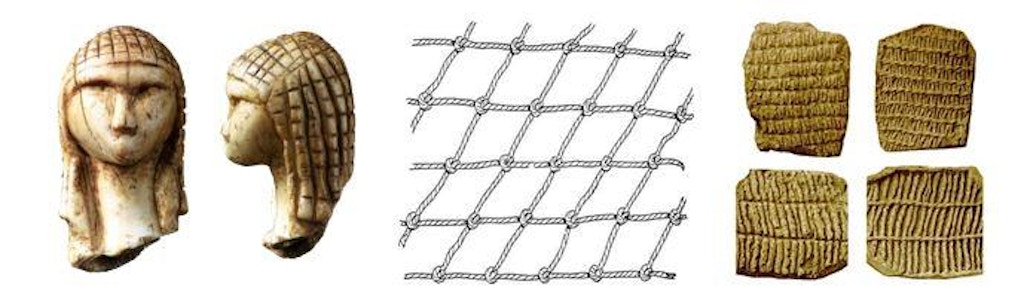

The origin of textiles is unknown. However, over the centuries, thousands of samples have been excavated from all over the world, the oldest being that of the Gravettians, an early culture of the Paleolithic period, dating back approximately to 33,000 BCE. These sites uncovered the earliest preserved textiles and other fibrous works that over the millennia had been ossified and fossilized into stone. Regardless of their beginnings, in studying the various fabrication methods used in the creation of the early textiles, they share a common theme — that of knotting, looping and braiding, resulting in products of spectacular variety and complexity.

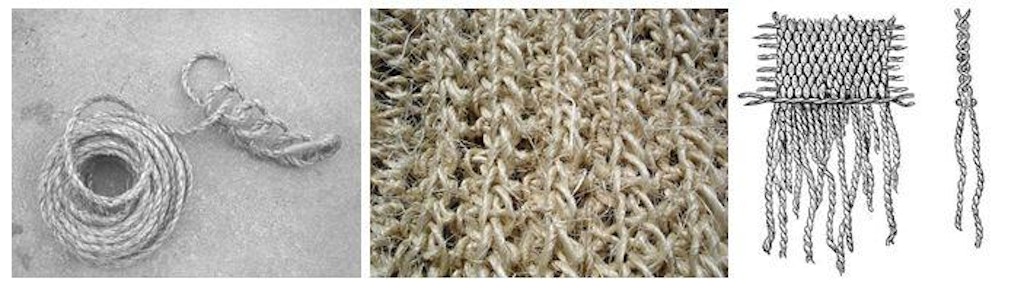

In the earliest textiles discovered, a form of knotless netting was used. This technique, Naalebinding, uses a needle to loop fiber back on itself. A single open knot is stitched and subsequent loops are threaded through the previous stitch. Naalebinding is the earliest known textile technique upon which all other textile procedures are based. This process establishes a set of steps or rules that guide its fabrication. Those skilled in these methods know these instructions as a textile pattern. By employing the simplest of loops, the variety of different fabrication sub-techniques is staggering, even in the oldest of textiles discovered. These looped fabrics were typically used for nettings and garments, primarily due to the fact that the looping technique imbues the fibers with an elasticity that did not previously exist in the unprocessed threads.

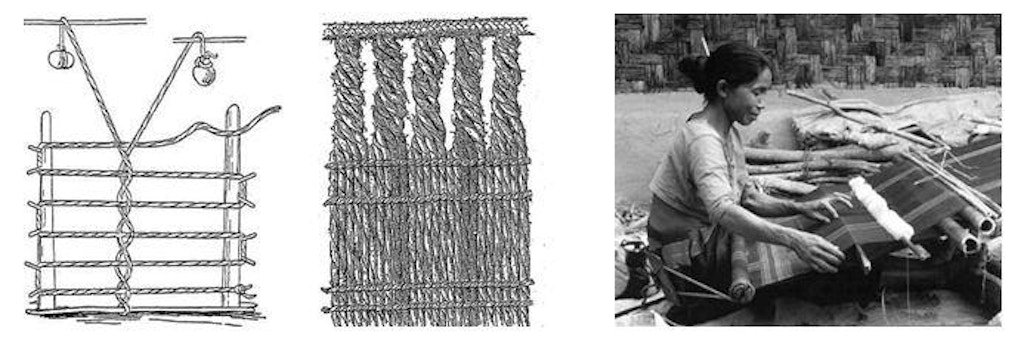

From these knotless netting techniques, similar to that of crochet, larger swaths of textiles most likely gave rise to the creation of loomed weaving. Unlike the looping of threads, weaving uses a crossing of threads in a bidirectional manner called warp and weft. This crossing pattern promotes an efficient use of material and effort resulting in a much larger and tighter finished product and one that is more resistant to rain and wind. Because of the nature of the woven textile, it is likely that the large textiles used in the first huts and shelters utilized this technique. However, due to the looping process, the warp threads must be tied off. Here, the looping and knotting techniques are reintroduced at the fringes. As a result, these techniques work in tandem and each textile procedure is used for the expressed purpose while maintaining an artful approach to the end product.

As peoples, tribes, and cultures began to develop, the nomadic hunters and gatherers settled into an agrarian lifestyle. The use for textiles as shelters shifted. No longer did the shelter have to travel with them. Instead, their lodgings became more permanent. Alongside this radical shift of living was the development of certain machines to aid in the daily chores. As with all invention, the introduction of new tools shaped and influenced man’s environment and, ultimately, his thinking. As soon as inventions began to supplement a laborious task, these early peoples adopted it in order to apply energies to other areas of life. This is where technology finds its place — alongside the endeavors of man, and a simultaneous evolution born out of necessity. This wedding of tool to augment activity is found in the early needles of the Naalebinding. But with an increased complexity in the processes of weaving, comes the creation of the manual loom. This relatively innocuous device, steeped in a tradition of textile fabrication, is at the heart of great tapestries, fine silks, and more unexpectedly, that of a digital revolution.

Domains: From Analog to Digital

All textile fabrication, regardless of its style, uses a set of rules in order to execute the specific works. Although many use the terms like Weaving, Naalebinding, Crochet, and Knitting interchangeably, they are all very different in both procedure and execution. The latter three are primarily hand techniques using simple hooks or needles, whereas weaving uses many threads and requires a jig and, for larger textiles, a laydown space. This looming process is systematic and follows a distinct set of procedures in order to achieve the final woven product.

In the first incarnations, these hand and ground looms were used to weave fabrics for rugs and tented enclosures. As cultures and societies developed into large civilizations, the demands for textiles grew. With this evolution in human ecology, people continued to invent new contraptions for various things, including more robust textile machinery. As the weaving looms evolved, so did the complexity of the patterns. With the onset of these complex new patterns and high demand of the population, weavers became overburdened, resulting in mistakes and delayed product. As a result, the need for a new approach to this process was essential, and in the late 18th century, the first semi-automatic pattern-generating loom was created.

The inventor of this complex loom, Basile Bouchon, was a textile entrepreneur and the son of an organ player. His machine created detailed arrangements by employing a long scroll of perforated paper, borrowing the concept from brailed music boxes. The holes in the paper held needles in place as the weaving shuttle moved back and forth, resulting in the development of a pattern that was extraordinarily difficult to achieve by hand. As with many inventions, the problems solved gave rise to new demands, which pushed the loom to evolve. Jean Baptiste Falcone, Bouchon’s assistant, replaced the perforated rolls with solid punch cards to eliminate errors produced by the tearing of the paper. Innovation continued at the hands of Jacques Vaucanson, who attempted to automate the process, an effort that remained unsuccessful until Joseph-Marie Jacquard.

Known today as the Jacquard loom, this machine was the first to autonomously compute and execute a pattern using punch cards arranged in a long band. This series of solid cards enabled the binary rules of over and under to be executed without the need for any human intervention. Through the years, textile machines became more efficient and even more complex. With the push for mechanized automation, along with the application of binary logic, these procedures, steeped in the making of textiles, were appropriated to program the first complex calculators.

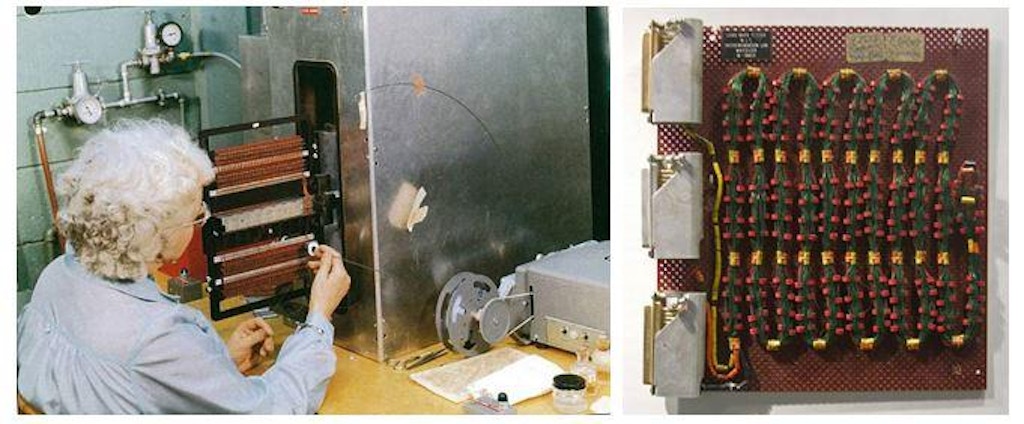

Originally the size of entire rooms, these enormous computers could do highly advanced calculations using punch cards—the very same technology stemming from the perforated paper used by Bouchon. During early stages of the Apollo missions, there was an issue in guiding the lunar modules on the dark side of the moon. Engineers at Raytheon, along with mathematicians at MIT, developed a concept for coding programs that would automatically guide the craft, which became known as the Apollo Guidance Computer.

This array of modules stored programs of Read-Only Memory (core rope memory), which was created by the threading of copper wire either through or around a magnetic transistor in order to code the program. When the copper wire is threaded through the transistor, the code is read as a one (1), but if around the transistor, a zero (0). In order to fabricate these modules with the required consistency and precision, workers experienced in fine weaving and lace were hired to weave these complex programs. This technology was called LOL memory, an acronym which stood for Little Old Lady. Regardless of the name, the fabricators of these modules are celebrated for their works not only in textiles, but in the advancement of digital technology.

Ultimately, LOL and core rope memory were the foundation of the digital revolution. The lineage of today’s ubiquitous smart phones and micro-circuitry can be traced back to the beginnings of a rule-based fabrication of the earliest textile techniques — over and under, yes and no, zero and one. It is with the aid of the machine, in augmenting effort, not replacing it, that man has been able to prosper. Without the textile to define the set logic and process, the development of such advancements would not have been possible. So what can be learned from this? In a world seemingly split between a physical and digital environment, perhaps we should look into what the textile can teach us relative to the virtual world it helped create.

A Consequence of Innovation

As mentioned previously, the introduction of any new paradigm demands the attention and full involvement of its creators. The digital revolution is no exception. However, unlike previous technological advancements, this new digital environment has the ability to draw one in so deeply that the physical experiences and haptic nature of the material world are transformed into novelty — a secondary stage in which virtual experiences operate. With digital technology developing at light speed, its influence on the evolution of the built environment is astonishing. With this comes risk, as Semper described shortly after the industrial revolution: “Innovation and implementation of new technologies would enable us to rise above our past. It is imperative that these means and techniques be used to their fullest extent. Failure to understand and master new technologies, while applying critical judgment to the result, will only lead to the rapid regression of our culture.” With the unchecked usage of the digital tools in conceptualization, design, and development of architecture, these concerns are just as apt today. Regardless of the digital domain, the built environment consists of real materials and exists as manifestations of physical reality. Therefore, a balance of play must be found between both the physical and digital environs.

Experimentation: Augmenting Textile and Process

In the encouragement of the virtual, there has been a push, as with all new technology, for its immediate and prolific application, especially in architecture, where digital programs are used to generate form and document the construction methods. Due to the immateriality of simulations, along with the ability to suspend the laws of physics, this new territory of digital exploration encourages the development of wild, implausible, self-intersecting forms. However, to heed the warnings of those before, it is critical to approach the use with feet grounded in physical reality. By doing so, a playful game between the analog and digital begins. The analog, specifically that of textile modeling techniques, can aid designers in the conceptualization of form and surface, while the role of the digital tool is utilized to augment the result. Here, the textile is established as the generator of form and concept, steeped in a deep history of materiality and technique.

By tracing the lineage and history of fiber techniques, it is clear that the exploration of these textile techniques is limitless and can lead to new and astonishing innovations. Similar to the Apollo missions, it is important to actively explore all domains in order to arrive at a method that engages the capabilities of the software and the techniques so that the two work in concert. In studying the lineage of the built environment, it is a small leap to apply these early techniques in the definition of space, form, and enclosure.

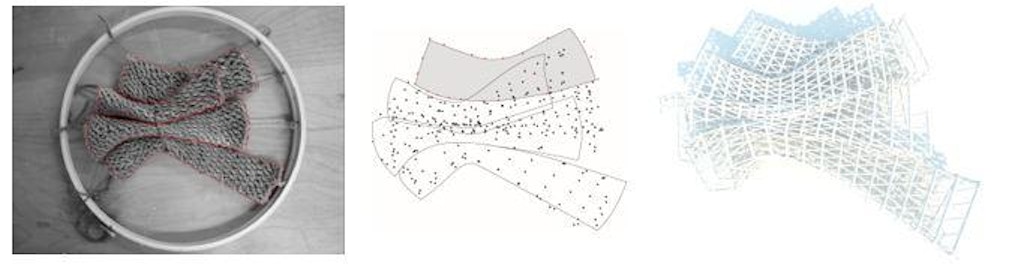

Due to the varying styles, there are many textile techniques that can be utilized, but it is important to understand how the elemental concept of looping fibers can lead to a new application of modeling in architecture. With that, one can look to Naalebinding and its cousin, crochet. Often seen as a handicraft and deemed to be a simple pastime or folk art, in recent decades, crocheting has become a powerhouse of exploration in advanced modeling of complex mathematics and geometries. In 1997, Daina Taimina, a Professor of Mathematics at Cornell University, was the first to realize crochet’s unique capacity for fabricating complex geometries, specifically the negative curvature of hyperbolic surfaces. She realized that the mathematical formulas for these surfaces could be translated into a crochet pattern. This was achieved by looping a stitch into the same space twice in an exponential pattern, resulting in a pliant hyperbolic surface.

From there, this technique of using computational formulations and translating them into crochet patterns took off in the fiber arts and mathematics communities. From these explorations in hyperbolic geometries, others have exploded how digital models can be transformed into a pattern or code and crocheted by hand. As a result, this augmented process creates a dialog between the digital script and analog fabrication. It is not solely a top-down or a bottom-up process, but rather recursive middle play where technique drives the digital pattern, and the pattern results in the physical model.

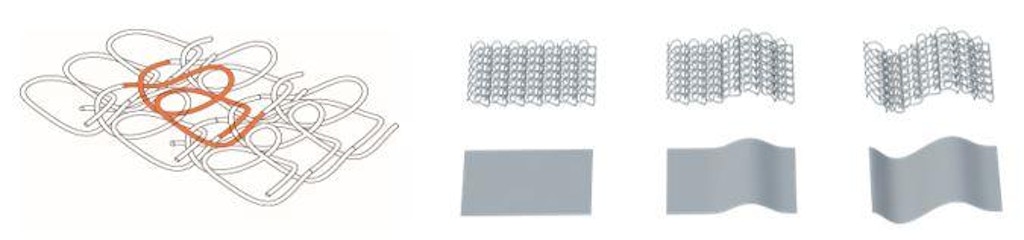

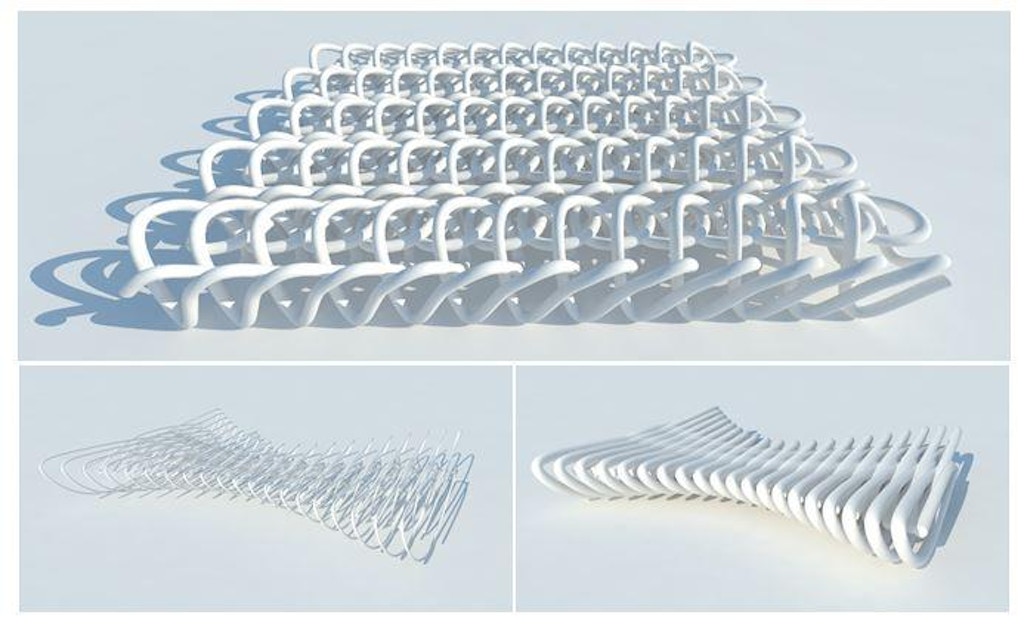

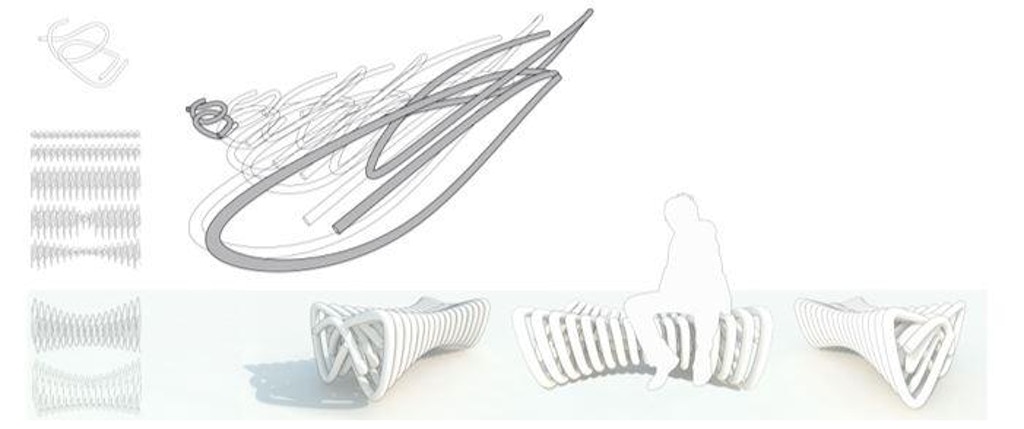

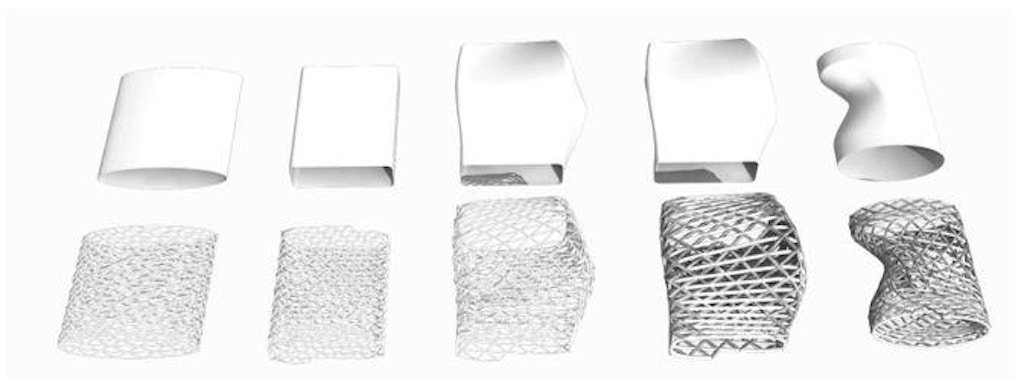

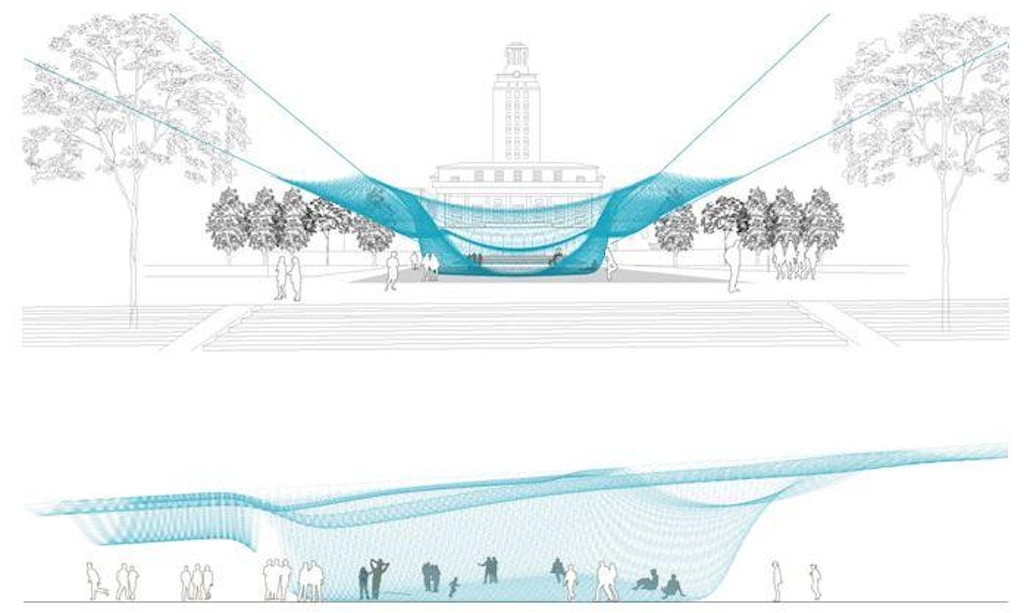

From these interesting crocheted forms, the jump to large structures and spatial architecture is no different than that of any modeling method using basswood and foam block models. Unlike these typically static model-making techniques, crocheting and other textile techniques like knitting, knotting, braiding, and weaving, find a balance between the analog models and the digital programs. They metabolize the pliant fiber models into defined architecture. Within both the physical reality and digital environments, there are two distinct categories of operation that can be utilized for experimentation— Generative and Transformational techniques (Rahim, 2007). Though these techniques were first defined within the realm of the digital, they apply to the pliant fabrication techniques of the material world as well.

Generative techniques are the coded, rule-based applications that inform the development of the structure. An example of this is the looping, weaving, knotting, or braiding of fibers, which result in the creation of a product that is inseparable from the technique used to create it, such as the crocheted hyperbolic surfaces. In action, a square, triangle, and circle evolve through the application of exponential loops into hyperbolic versions where the base geometry is coded into the final product.

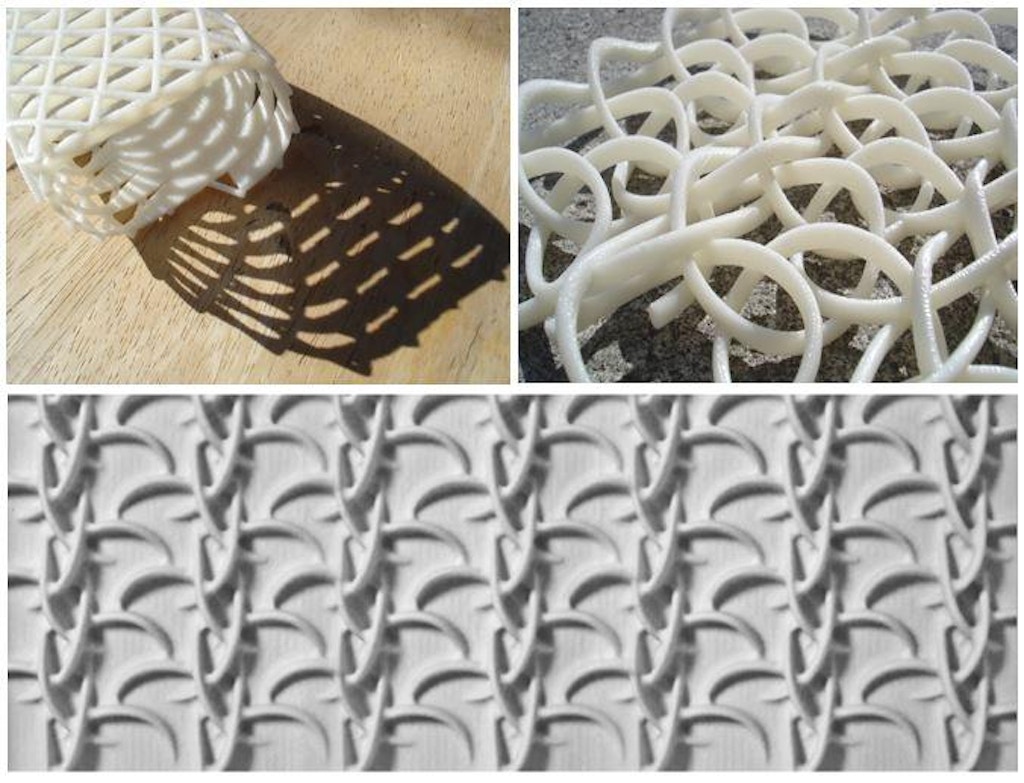

Transformational techniques are quite different and are the geometric or force manipulations acting on a defined form. This process is applied to an object and is an external operation. Some examples are stretching and pleating. Here, the forces applied to the specimen are bound by the generative process but have the ability to force the reconfiguration of the material and its base code. A prime example of this is observed in the overstretching of a crocheted tube. In the overstretching, the slipstitched loops reconfigure themselves, giving rise to a new pattern and optimized structure, that of a triangulated diagrid arrangement. This transformation of pattern and its overall result enables the designer’s decisions to be steeped in a material intelligence rather than the superimposition of a gridded configuration on a form.

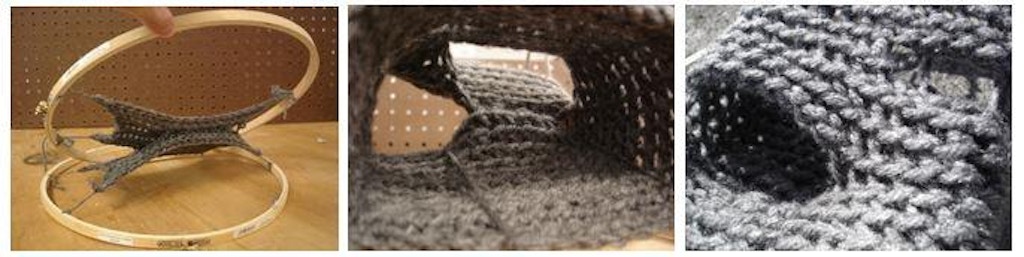

Using these methods promotes a playful approach to material and technique while operating in the tactile domain of physical space. However, other notable techniques use the application of a liquid agent to aid in the development and exploration of form and structure. An illustrative example is that of Frei Otto’s wool thread experiments, by which a kaleidoscopic grid of threads are bound by a ring, loosened then dipped in water. The surface tension of the water pulled the threads to one another, creating a natural result, one that can only be achieved by allowing the playful interaction of the frame, threads, and liquid.

Another way of using fibers and liquid agents to explore more practical applications is by the immersion of a textile system into a hardening substance like lacquer, plaster, or porcelain. By doing this, the pliant textile is embedded with new information from the liquid agent. In lacquer, the liquid hardens the threads together resulting in a still flexible surface, but it has a memory of the form in which it cured. The plaster example hardens completely, but similar to fiberglass, has an increased strength due to the wedding of the two materials. Finally, the porcelain agent, when dipped multiple times, results in a porous structure that only references the basic pattern of the original textile. Similar to the nomenclature of the digital tools, when baked, the fibers surrounded by the hardened porcelain are burned out, resulting in a hardened ceramic structure. Though it has lost the pliable nature of the textile, the overall form and effect are informed by the original.

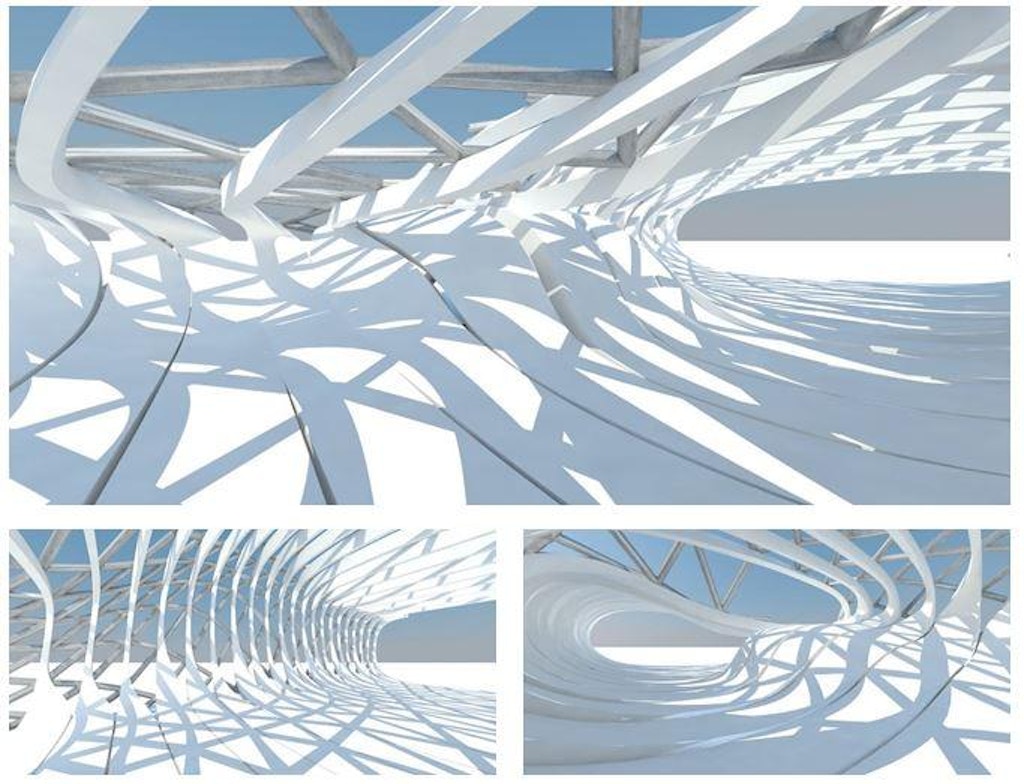

These experimentations are the embodiment of Semper’s Theory of Stoffwechselthese or Transmaterialization, where, through processing, the concept or manifestation of one material, specifically textile, is appropriated by that of another. Through this metabolic process, Semper stated that “all operations in textile seek to transform raw materials with the appropriate properties into products, whose common features are great pliancy and considerable strength, used as pliant surface to cover, to hold, to dress, [and] to enclose...” In today’s digital age, this application of exploration occurs in both realms of the virtual and physical realities, and the processes used in the fabrication of the built environment have the opportunity to oscillate between these two realms. The results of this interactive play from handicraft techniques, augmented through the application of the digital proxies and tools, lead to fantastical textures, forms, and spaces.

Similar to the acting liquid agents, the fluid and parametric properties of this digital domain enables an exploration of a new type of textile. By using a textile technique and material, the digital model is steeped in a material intelligence rather than just being at the whim of the programmatic constraints. The digital setting does enable something that the analog model is not easily capable of — the scalability and suspension of physical properties. Just as Semper suggests, man transmaterialized textile into carved stone, and the Gravettian garments fossilized.

The process of applying a likeness, a relational framing from one material to another, occurs similarly in the digital translation. Dennis Dollens states: “Virtual Space becomes an arena for speculation and contemplation, for testing, turning, warping, morphing and animating spatial sequences that otherwise would remain static graphic images. (The) digital space becomes a contributor to the development of ideas and forms, not merely a passive host to preconceived shapes or prescribed software formats and output (Dollens, D. 2001).”

It is important to realize that once digitized, these complex models and structures are at the whim of the capabilities of current fabrication technologies. Scale from model into architecture finds itself with the same problem early peoples did with larger woven textiles. The new inventions create new demand, which results in new machines. With the continual evolution of digital fabrication technologies and parametric tools, designers may find that these textile techniques and handicraft pastimes may not only aid in the conceptualization of their ideas but may be the next evolution in digital fabrication. The key is in the understanding that new inventions are to be used to augment human efforts but not supplement human judgment or intervention. Allowing the rigors of involvement of the human spirit to be sublimated by the autonomic process of the machine or digital environment could quickly lead to what Semper feared — a rapid regression of man and his culture.

Experimentation: Conceptual Application

The Rear View Mirror: A Potential in Textiles

As man evolves, it is likely that more problems will arise in both the physical and digital environments. With these new tools, it is important to understand their place in the world and understand the history behind them. It’s interesting to think that at the beginnings of this digital age, there is a textile machine that derived patterns based on punch cards. When it comes to architecture, it is important to know how to use a tool and the history behind it. There are many things to be learned by taking up sewing, crocheting, weaving, or pottery, beyond the benefits of doing something for the sheer joy of it. These pastimes and handicrafts can aid in the generation of ideas and insights beyond that of design studio. Marshal McLuhan said, “There is absolutely no inevitability so long as there is a willingness to contemplate what is happening.” So long as there is continued experimentation, play, and participation in the processes of the physical environment, the door is open to unexpected inspiration and beauty. Some may believe that there is nothing new under the sun. However, man’s ability to artfully explore material and his environment has no bounds.

Acknowledgements

I would like to thank all those who have supported the application of analog modeling and textiles in the field of architecture and to all who mindfully approach new technologies. This paper is dedicated to Elenora Lahoda, thank you for teaching me how to crochet.

Rights and Permissions

Dollens, Dennis. D2a, Digital to Analog. Santa Fe: SITES, 2001.

Holmes, William Henry. Prehistoric Textile Fabrics Of The United States. Smithsonian Institution, 1881

McLuhan, Marshall. Understanding media: the extensions of man. Cambridge (Mass.): The MIT Press, 1965.

Potter, Annie. A living mystery: the international art & history of crochet. United States: A.J. Publishing International, 1990.

Rahim, Ali. Catalytic formations: architecture and digital design. London: Taylor & Francis, 2007.

Semper, Gottfried. The Four Elements of Architecture and Other Writings. Cambridge University Press, 1989.

Taimin̦a, Daina. Crocheting adventures with hyperbolic planes. Wellesley, MA: A.K. Peters, 2009.

All figures are public domain or work of the author unless otherwise credited.

Author Comments

Additional Readings

Ettlinger, Or, Peter Krečič, and Fedja Košir. The architecture of virtual space. Ljubljana: Faculty of Architecture, 2008.

Otto, Frei. IL25: Form Force Mass. Institute for Lightweight Structures, 1990.

Otto, Frei. IL14: Adaptable Architecture. Institute for Lightweight Structures, 1975.

Spuybroek, Lars. The Architecture of Continuity: Essays and Conversations. Rotterdam: V2 Pub. 2008.