Let Thin Glass in the Facade Move

Thin Glass - New Possibilities for Glass in the Facade

Sign in and Register

Create an Account

Overview

Abstract

Facades play an important role in the control of energy flow and energy consumption in buildings as they represent the interface between the outdoor environment and the occupied indoor space. New approaches to sustainable building solutions lead to the option of regulating internal and external conditions being of great relevance. Studies on climate adaptive facades show a very high potential for improved indoor environmental quality conditions and energy savings using moveable facades. A number of movable facades have been realized in the past, but the use of thin glass with a thickness of 0.5 mm to 3 mm opens a brand-new area that makes it possible to play with the geometry of the outer skin and provides an opportunity to make it adaptive by movement.

Thin glass requires curved surfaces in order to gain structural stiffness in static use. In kinetic facades the high flexibility of thin glass allows for new possibilities concerning changes in size and position by bending the elements rather than using hinges in a system of foldable rigid panels. The geometry is based on the known theory of developable surfaces for keeping a low stress-level during movement. This allows for facades made from cold bent thin glass or curved laminated safety glass (produced by the laminating of thin glass plies), a greater simplicity in construction, robustness and durability of moveable components. These movable systems also may be actuated autonomously.

By applying the principles of conventional moveable facades to bendable geometries, a new toolset for the design process by architects may be provided. Some approaches based on the previously mentioned theories were created to both clarify some concepts and discuss their principles and applicability.

Authors

Prof. DI Dr. Jürgen Neugebauer

University of Applied Sciences, FH-Joanneum

juergen.neugebauer@fh-joanneum.at

DI Dr. Markus Wallner-Novak

University of Applied Sciences, FH-Joanneum

markus.wallner-novak@fh-joanneum.at

Keywords

Introduction

Last year a research center, “Josef Ressel Center for Thin Glass Technology for Structural Glass Applications”, was launched and deals, for example, with the topics of the determination of the

Access Restricted

What is Thin Glass?

The differentiation between “thin” and “regular” glass requires more than just the definition of a thickness limit, e.g. “everything below 3 mm is thin glass”. It usually depends on the

Access Restricted

Products

Besides “regular” float glass for window panes, which can also be produced in thicknesses far below (and above) the standard thickness of 4 to 12mm, a wide variety of specialized

Access Restricted

Production of Thin Glass

For the production of thin the following processes such as float glass, both down-draw and up-draw or the overflow fusing process can be found on the market (Neugebauer, 2016).

Float

Access Restricted

Bending Strength of Thin Glass

One approach is to determine the stress using equations (1) and (2). The bending moment can be calculated with equation (1) based on the differential equation of bending theory and

Access Restricted

Method

Kinetics in façades is sometimes dismissed as irrelevant owing to experiences with very complex and consequently fault-prone façade-systems. However, simulations show that the energy consumption of a Central-European office building

Access Restricted

Data

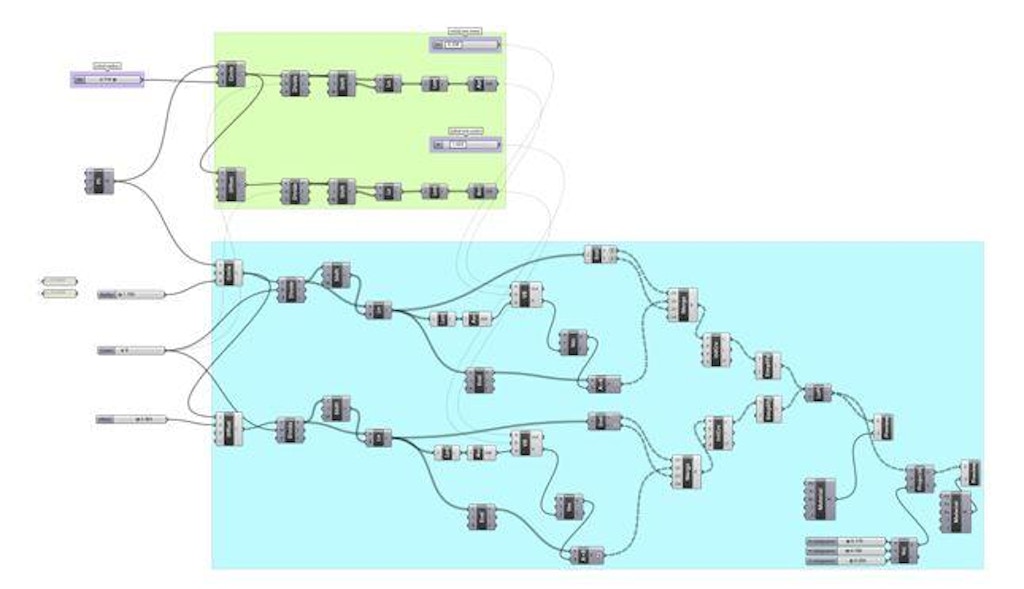

Several models were created using the visual programming language of the generative modelling interface of Rhinoceros 3D by McNeill Associates (Fig. 8). The authors picked out three applications of different scales: a sun shade, an air flow control and a moveable façade.

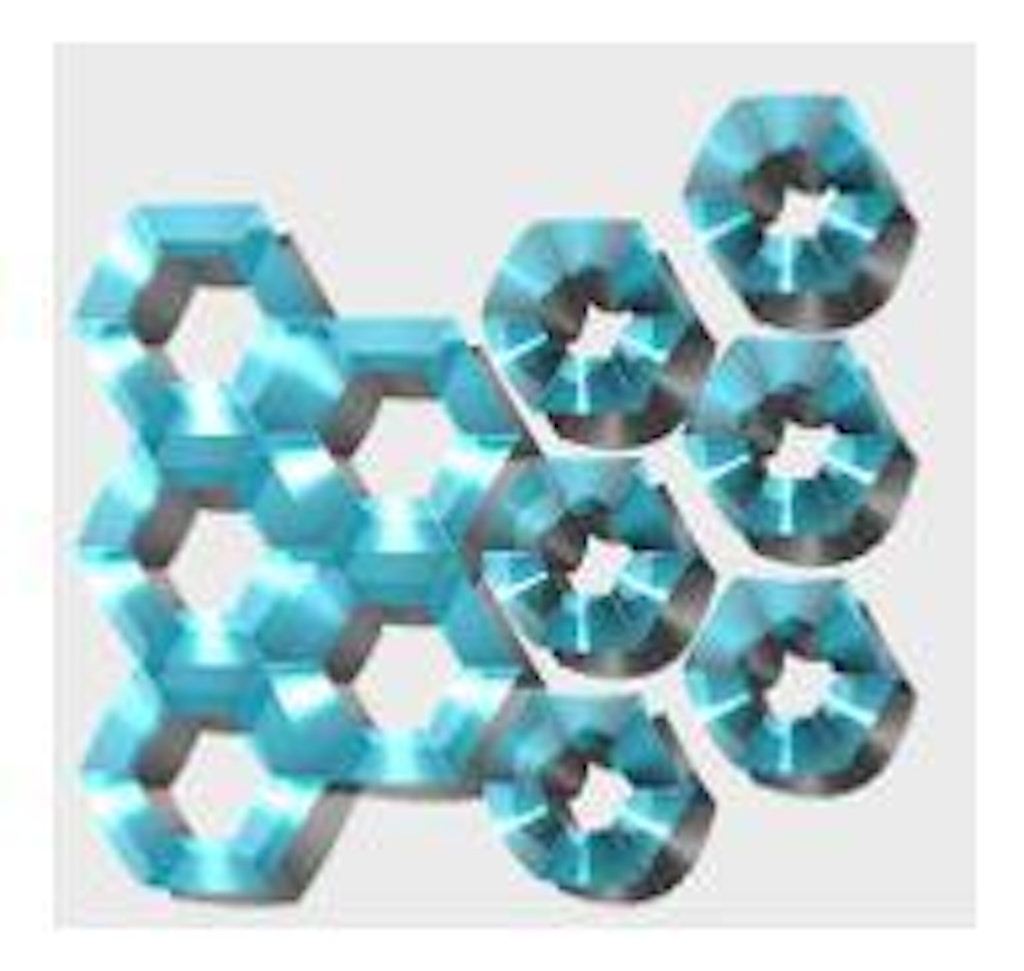

Sun Shaded Tessilation

The idea behind this model is a ring-shaped hexagon with a central hole that may be opened and closed like in an enlarged camera aperture. In the example shown, the opening area in a closed state measures about 40% of the one in an open state.

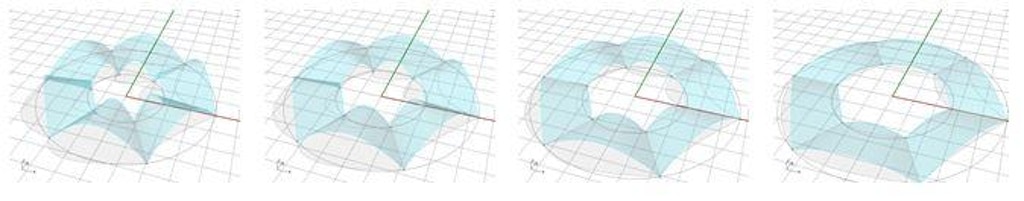

The kinematics involved are translations about concentric lines. The thin glass elements are bent from lower to higher curvature keeping their conical shape (Fig. 7).

Simple linear rails and slotted links may be used as a guide. As active actuators, gears on a tooth rail may be used or as an alternative, a passive temperature sensitive actuator may be involved.

The hexagonal grid may be used as a basic tessellation element in larger structures (Fig. 9).

Opening Elements

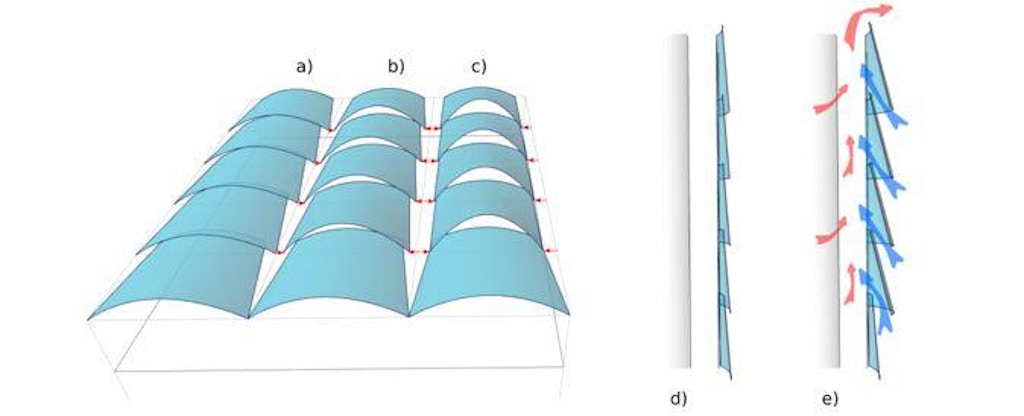

In variant A, vertical conical elements overlap like pantiles of a roof. By moving the end points of the lower base curve of any of the truncated cones closer together, the rise of the curve is increased (Fig. 10). This leads to an opening in the horizontal plane. Kinematically, the endpoints move along a straight line. The glass surfaces stay conical during their movement. As a guide small rails at the curve ends may be used. Either two synchronized active actuators such as motorized jackscrews may be used for each cone base as an actuator or passive actuators with crank mechanisms may be employed.

In Variant B, two vertical cylindrical elements of parabolic base have a common generating straight line. By rotating this straight line, the two cylinders change shape to form two conical surfaces with base curves of a different rise (Fig. 11). This principle may be used to open the façade and control the air flow. The guide is done by a pin support at midpoint of the profile along the common generating straight line. Actuation may be carried out either actively by pneumatic jacks or a passively using a rotational spring made of bi-metal.

Folding Façade

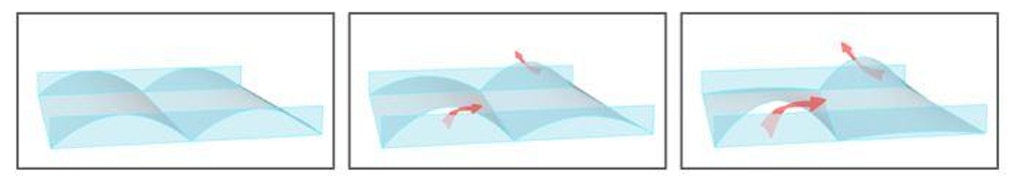

Another example is a flexible façade based on the principle of curved folding. Thin glass is cut along curved lines (curved folds) into different elements and these elements are assembled together rotatable along these curved lines. This concept shows a movement and deformation of the glass elements both inwards and outwards of the façade level, due to an in-plane, such as, for example, pressure driven gear. Figure 12 shows a visualization of a parametric study with the help of Rhino 3D together with Grasshopper 3D.

Conclusion and Future Work

The aim of this research work is to find new fields of application for thin glass in buildings. One kind of new application is the field of movable and adaptive

Access Restricted

Acknowledgements

This paper is the result of a project by the research center named the “Josef Ressel Center for Thin Glass Technology for Structural for Structural Glass Applications” funded by the Austrian “Christin Doppler Research Association” and is supported by industry partners SFL technologies GmbH and LISEC Austria GmbH.

Rights and Permissions

Carter S. Haines, Márcio D. Lima, Na Li, Geoffrey M. Spinks, Javad Foroughi. “Artificial Muscles from Fishing Line.” Science, 343, 868 (2014).

Holstov, Artem, Graham Farmer, and Ben Bridgens. “Sustainable Materialisation of Responsive Architecture.” Sustainability, 9 (2017): 435.

Kasinalis, C., R.C.G.M. Loonen, D. Cóstola, and J.L.M. Hensen. “Framework for assessing the performance potential of seasonally adaptable facades using multi-objective optimization.” Energy & Buildings, 79 (2014): 106-113.

Moloney, Jules. Designing Kinetics for Architectural Facades. Oxon: Routledge, 2011.

wikiarquitectura. Al Bahar Towers. 2 10 2014. https://en.wikiarquitectura.co... (accessed 9 5, 2017).

Winstanley, Tim. AD Classics: Institut du Monde Arabe / Enrique Jan + Jean Nouvel + Architecture-Studio. 2 10 2010. http://www.archdaily.com/16210... (accessed 9 5, 2017).