Case Study: Renovation of Fountain Place

Innovation in Jumbo Clear Span System Applications

Presented on October 12, 2022 at Facade Tectonics 2022 World Congress

Sign in and Register

Create an Account

Overview

Abstract

Fountain Place is a project that exemplifies the latest technology and applications in building skin design and jumbo structural glass applications, with a core emphasis on innovation in engineering, design, fabrication, and installation. This case study describes the clear span glass wall design strategy in detail - including system design iterations, structural optimization, and final system selection. The paper focuses on a novel design approach that was developed to minimize glass deflection, simplify installation, and ensure alignment of the jumbo clear span wall glass panels. Installation and manufacturing challenges are also covered in depth to familiarize readers with the hurdles encountered over the course of the project execution in achieving the desired tolerance, optical quality, and system transparency goals.

The frameless, clear span, jumbo glass walls of the Fountain Place renovation are supported using a unique adjustable perimeter support system that allowed the designers to eliminate all support framing within the clear opening and resulted in a highly transparent installation. The design methodology and connection details represent a technology advancement in that they simultaneously allow for fixity against glass rotation, inter-story drift isolation, and installation adjustability while minimizing the façade system deformation.

Authors

Alfonso Lopez P.E.

Principal and CEO

Sentech Architectural Systems

alopez@sentechas.com

David Dunham P.E

Director of Business Development

Sentech Architectural Systems

ddunham@sentechas.com

Diarmuid Kelleher P.E., S.E.

Director of Engineering

Sentech Architectural Systems

dkelleher@sentechas.com

Keywords

Introduction and Background

As glass manufacturing capabilities have evolved, the availability of larger panel sizes, makeup, curvature, and the evolution of overall glass quality (bow tolerances, optical quality) has enabled architects to imagine and design facades that span entire openings, while completely eliminating opaque zones and hardware. This has demanded not only huge investments from fabricators in machines, autoclaves, tempering furnaces, and coating lines, but also meteoric advancements in the engineering and design technology needed to safely address forces, drift, panel movement, adjustability, and installation challenges.

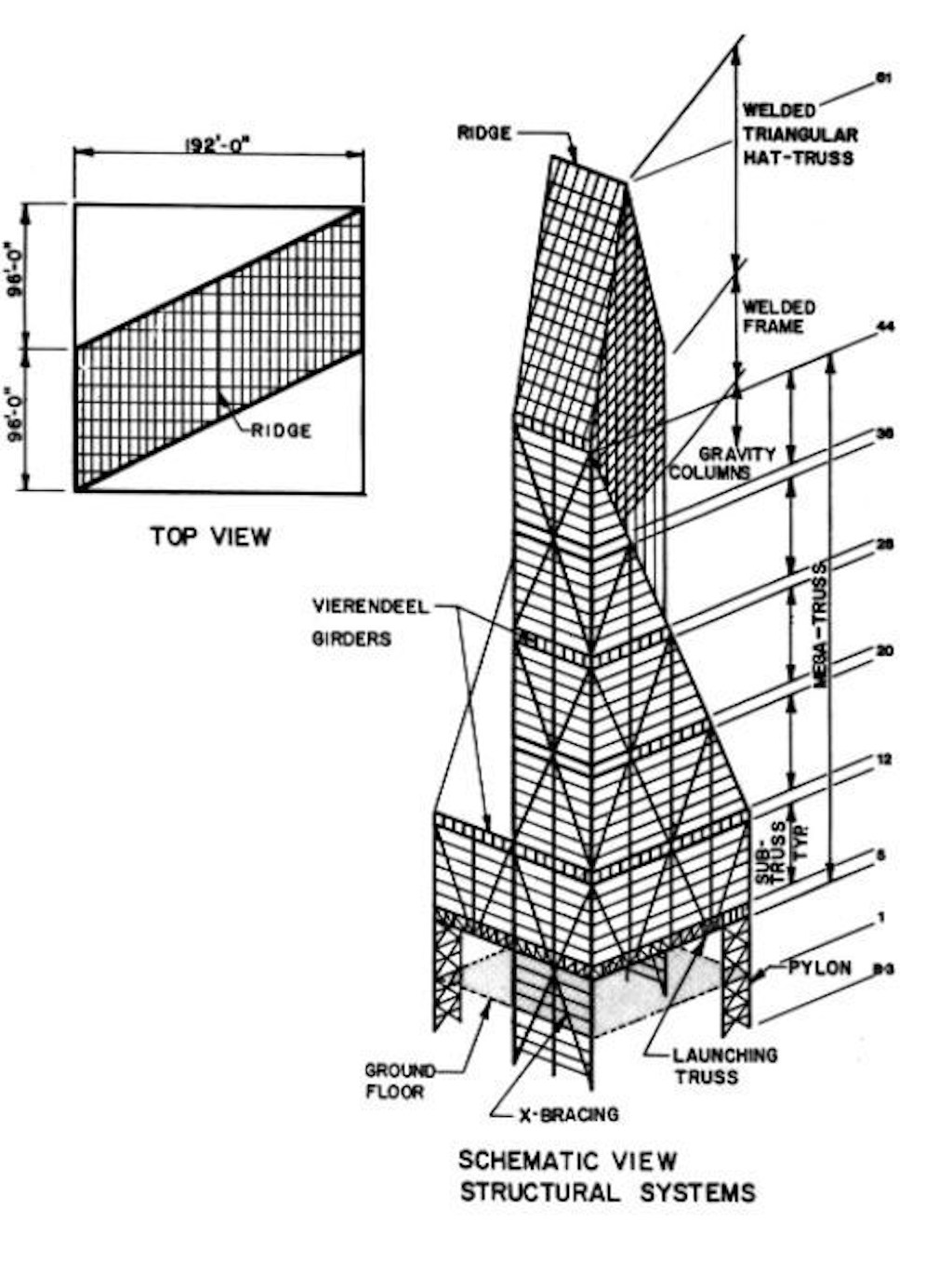

Fountain Place – a 60-story landmark structure that defines the Dallas skyline- was originally designed by I.M. Pei and Partners (now Pei Cobb Freed & Partners) from 1982-1986. In 2016, executive architect Gensler and architecture firm James Carpenter Design Associates were tasked with the renovation of the interiors, as well as the transformation of the entry experience. The original mezzanines (see figure 2 below) were removed, and a 30-foot-tall jumbo glass façade was envisioned to take its place (see figure 3 below).

Figure 3: Sentech Architectural Systems. 2021. "Fountain Place Structural Glass Façade”. www.sentechas.com/projects/fou... project execution demanded single source responsibility, and as such, a single firm was selected to design, engineer, and supply all materials for the construction and installation of the façade. This included glass sourcing, testing, and the manufacturing of the perimeter support structure. The clear span design approach had to fit the design mandate of complete transparency- the vision of a structure that would enable a harmonious transition between the interior lobby space and Dan Kiley’s renowned outdoor water gardens. As the design progressed, innovation and creativity on the engineering front became imperative to realize not only the aesthetic and optical quality elements of the structure, but optimizing the structure for safety, redundancy, retention, and overall performance of the delivered, installed system.

Design Strategy

The 29’-6” tall, laminated façade panels were designed as a clear span from ground level to the second floor and are supported by a continuous steel channel at the base

Access Restricted

Design Iterations and Structural Optimization

Both the strength and rigidity of the perimeter connections was coordinated with the design team to ensure accurate predictions of the panel deformation under wind loads. Since the upper support

Access Restricted

Design and Installation Challenges

The use of this design solution presented engineers with several challenges, all of which were addressed during the structure design phase. One of the most difficult challenges to address, was

Access Restricted

Conclusion

It was critical to establish continuous dialog during the design phase between the building design team and façade designers to achieve an optimal balance between the support rotational stiffness and

Access Restricted

Rights and Permissions

REFERENCES

Lopez, Alfonso L., P.E. and David Dunham, P.E. 2020. Seismic Design of Jumbo Glass Structures, Inter Story Drift Analysis. Façade Tectonics. www.facadetectonics.org/papers/seismic-design-of-jumbo-glass-structures

Kirschbaum, Ned, FAIA, CCCA, LEED AP, Peter Koukos and Alfonso Lopez, P.E. 2021. Realizing Bespoke Structural Glass Facades, The Denver Art Museum Welcome Center. www.facadetectonics.org/papers/realizing-bespoke-structural-glass-facades