Integration of Structural Glass in Historic Religious Buildings

The Christian Church was the largest agency for construction in northern Europe in the 12th century and the first to make glass an integral part of the architectural language of the building. The glass manufacturing processes of the time only allowed relatively small, thin and weak pieces of glass to be produced. Instead of letting this be an impediment to creativity, the designers of the great churches and cathedrals developed the construction methods that would result in the large, intricate stained glass windows that would become one of the main focal points of those buildings.

Religious buildings continue to embrace the new technologies that appeared in the 20th century and have allowed glass to leap from being used purely to provide access to light and protection to a material with load-carrying capability.

Two recent projects, the Lady Chapel glass wall at St. Patrick’s Cathedral and the glass awning at Trinity Church, show how glass can be integrated into religious buildings today. Both projects are located in New York City and were designed by Murphy Burnham & Buttrick Architects in collaboration with Eckersley O’Callaghan and fabricated and installed by Seele.

St. Patrick's Cathedral

St Patrick’s Cathedral is without a doubt one of the most iconic landmarks of New York City and due to its religious, architectural and historical significance, was declared an official New York City Landmark in 1966 and a National Historic Landmark in 1976.

The Roman Catholic Archdiocese of New York recently completed a $200-million, 10-year restoration project which included exterior and interior cleaning, repairs and improvements. With the constant flow of tourists visiting St. Patrick’s, the Lady Chapel could not serve as a quiet and intimate space as it was originally intended. The Archdiocese wanted an acoustical separation while visually keeping the chapel part of the main cathedral space.

The structural glass wall that was designed for this purpose consists of two main components: a 35 foot-tall laminated glass wall and a 13-foot-tall bronze-framed glass vestibule protruding about three feet from the wall above.

Figure 1 - View of Lady Chapel glass wall from nave

Figure 2 - Vestibule of glass wall

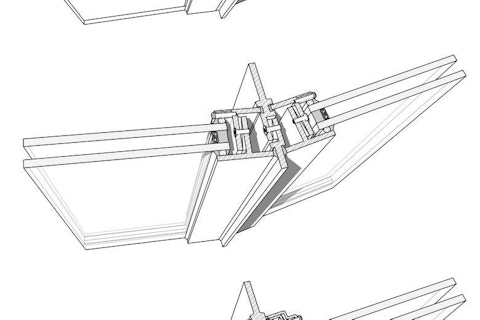

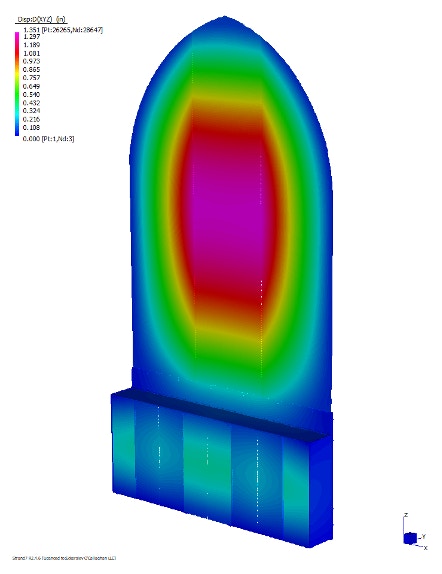

Three one and a half inch-thick heat-strengthened laminated glass panels make up the upper portion of the 48 foot-tall by 24 foot-wide glass wall. These glass panels are dead-loaded onto a two foot-deep laminated glass beam and restrained laterally on the perimeter of the building arch and joined together along the vertical joints with structural silicone, creating membrane action which limits the deflection under the five psf interior load required by code. Around the arch, the glass panels are captured in a glazing shoe consisting of intermittent glazing stops with continuous bronze cladding elements.

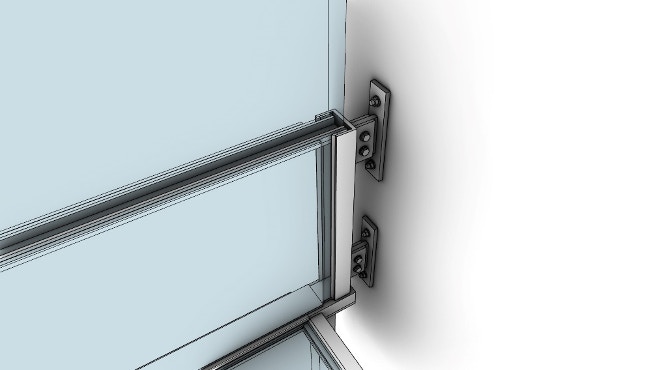

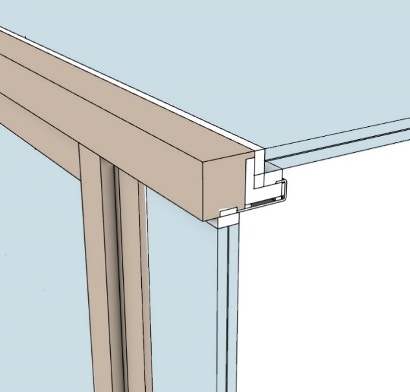

Figure 3 - Head connection detail

Figure 4 - FEA deflection plot of glass wall

The eight-ply, three and a half inch-thick, two foot-deep by 24 foot-long laminated glass beam has to carry the weight of the wall panels above (approximately 5,500 pounds per panel) and provide lateral support along their bottom edge. Because this bends the beam about its weak axis, it was connected to the vestibule roof panel which is used as a horizontal glass fin or diaphragm, stiffening the beam in the lateral direction.

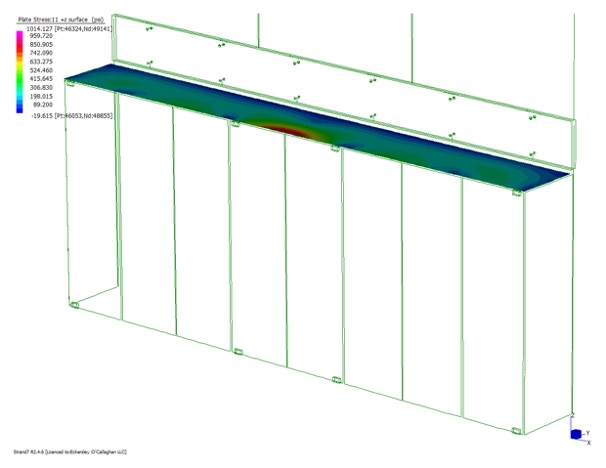

Figure 5 - FEA Stress plot of vestibule glass roof

Figure 6 – Section through laminated glass beam

To keep the beam from turning sideways, it is connected to the stone columns near the top and bottom edges. These brackets and stone anchoring were kept to relatively small dimensions by dead-loading the beam on steel posts at both ends, near the stone columns. The brackets therefore only need to transfer lateral loads.

Figure 7 - Beam connection to stone column

Finally, the vestibule consists of a bronze frame anchored into the floor slab, 21/32 inch-thick heat strengthened double laminated glass wall supported top and bottom and four frameless doors. In order to keep the metal framing as minimal as possible, one and a half inch square solid bronze members were used to make the eight posts and the frame around the vestibule roof panel.

Figure 9 - Vestibule roof and wall panels with bronze frame

Trinity Church

Trinity Church Wall Street in Lower Manhattan is the third building that the parish has occupied at this location in its 300-year history. In May 2018, the two-year $100 million rejuvenation project began with the goal of improving the accessibility and energy efficiency in addition to carrying out extensive restoration of the interiors and stain glass windows. Part of this project is the addition of a steel and glass canopy along the South side of Trinity Church.

Figure 10 - View of Trinity Church glass canopy

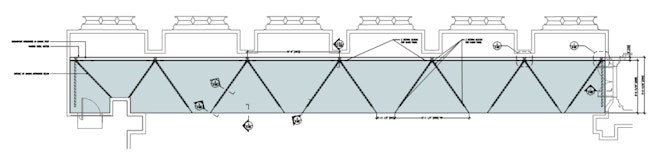

The nine foot-wide by 10 foot-tall canopy consists of triangular laminated glass panels supported on four and a half inch-wide by eight and a half inch-deep welded steel posts cantilevered off the new concrete ramp foundation structure. Each post splits into two tapered outriggers onto which the glass panels are structurally glazed. The spacing of the posts, approximately 15 feet, was primarily dictated by the rhythm of the church columns onto which they are centered.

Figure 11 - Canopy roof plan

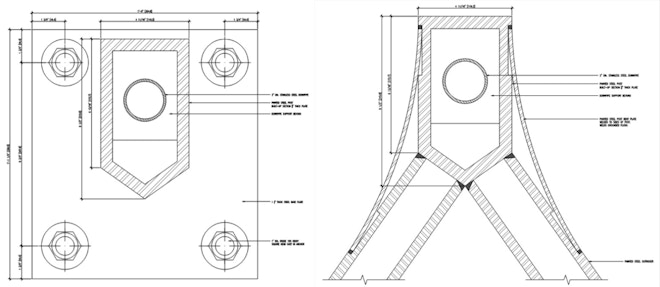

Figure 12 - Details of steel posts at the base and at the top connection with the outriggers

Figure 13 - Curved transition at post to outriggers

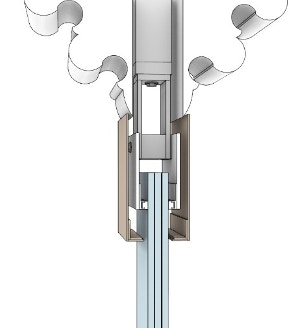

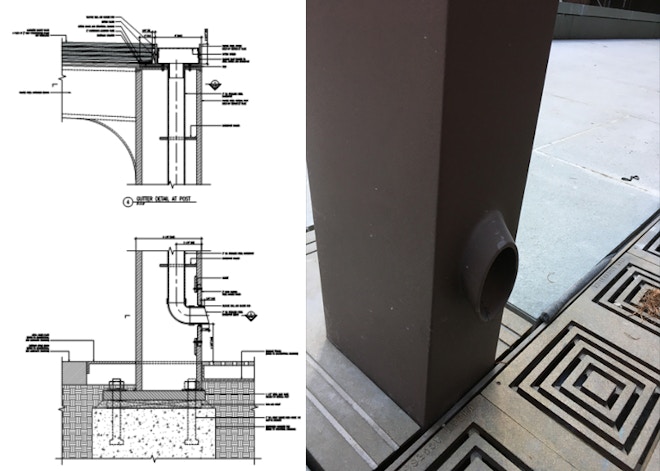

The two inch-thick laminated glass panels are structurally glazed on the steel outriggers and a continuous steel gutter running along the rear edge of the canopy. The gutters drain into stainless steel downspouts which are fully integrated into the vertical posts. The posts are fully sealed to prevent any water or moisture ingress that could cause corrosion of their interior surfaces and affect their long-term structural integrity.

Figure 14 - Detail and photo of integrated downspout

To provide a structure which looks as minimal as possible, no framing member was provided along the outer edge of the canopy. To further give the impression of lightness, the tapered outriggers stop short from the outer edge of the glass panels.

In order to reconcile the relatively large loads that the steel supports have to carry – the typical glass panels weigh about 2,000 pounds – and to create a structure as delicately as possible, the outriggers were pre-cambered and the posts installed slightly out of plumb in such a way that the steel supports moved to the desired target position once loaded with the glass panels.

St. Patrick’s Cathedral’s Lady Chapel glass wall and the Trinity Church glazed canopy demonstrate that structural glass can be a great solution to improve the functionality of a historic building without competing with its original fabric. Both projects present a successful juxtaposition where these new interventions reflect a modern expression through new materials, technologies and forms and the traditional styles and architectural hierarchies of their sacred spaces are respected. Structural glass offers the opportunity to create a balance between preserving the character and significance of an historic context and the need to adapt it to today’s demands, projecting it into the future.

Karine Charlebois

Associate

Eckersley O'Callaghan (EOC Engineers)

Looking for something specific?

Search our extensive library.

FTI’s SKINS email is the central source for the latest in building skin trends and research.

All emails include an unsubscribe link. You may opt out at any time. See our privacy policy.